Frame-tent barns

For large livestock, it is sometimes necessary to quickly erect a barn; such quickly erected structures are called frame-tent structures. They represent a base supporting a metal frame. It consists of steel lattice trusses fastened together by longitudinal girders.

The frame can be in the form of a half-barrel, or in the form of a gable roof. A special awning is pulled over the metal structures installed and fastened together, which is quite transparent and can transmit sunlight, while at the same time the awning does not allow precipitation to pass through.

Lifting parts of the awning, usually on the sides of the frame, allow for ventilation inside such a barn.

The disadvantage of such a barn is that it is not intended for keeping cows in the winter, and it is quite difficult to build a tent barn with your own hands.

Building a barn with your own hands: step-by-step instructions

Cowsheds are built using two technologies: framed and frameless. The frame method is considered more promising. Its main advantage is the speed of construction and ease of laying communications - ventilation, water supply, manure removal, etc. The construction of a small utility block consists of several stages:

Laying the foundation. Any - columnar for small wooden outbuildings, strip or monolithic for heavy buildings. Remove the top layer of soil from the area. They usually deepen it to 50–70 cm and fill it with crushed stone. With frame construction, this is where the laying of the foundation ends. To build a brick barn, a solid foundation is made - strip or monolithic. A trench is dug to a depth of 1 m, formwork and reinforcement cage are installed, the bottom is covered with crushed stone and filled with concrete. Roofing felt is laid on top as a waterproofing material.

Lay out the walls using a trowel and a building level, not forgetting to leave openings. To ensure that the walls retain heat, they provide good thermal insulation.

The roof is being installed. Wooden logs are installed at the top of the walls and sheathing is made. Then covered with roofing material. Slate is usually used as it is more accessible and cheaper. The ceiling is usually covered with reed slabs and plastered with clay. It is advisable to have an attic - this is additional insulation, you can store hay and other feed there. The roof of a barn without an attic must be insulated.

Install windows and doors. Carry out interior work

Particular attention is paid to the floors. Compact the soil, make a layer of roofing felt or slag and lay the floor with small gaps and a slope so that animal feces flow into the drainage pit

A layer of straw or sawdust is placed on top, to which peat can be added.

Cowsheds for a large number of livestock are built in a similar way, equipping each stall with a feeder 1 m long and 0.65 m high.

Barn ventilation

The simplest diagram of a barn ventilation system: an exhaust pipe made of boards is installed on the roof of the building. One or more, depending on the length of the room, equipped with a fan and a damper in case of bad weather. Fresh air enters the barn through the window openings. If there are none, then intake openings with dampers are created to allow air to enter at the bottom of the walls almost at the very foundation. Stale air is removed through an exhaust pipe.

Air exchange occurs by itself: warm air exits through exhaust shafts on the roof of the building, and cold air enters the room through special openings in the walls of the barn

To reduce the penetration of infections from the street, a box of sawdust is placed in front of the entrance, which is periodically moistened with creolin. In barns housing 200 or more animals, additional ventilation is provided in the form of a canopy on the roof.

Manure removal system

When keeping a small number of cows, manure is removed manually. In large barns, a mechanical manure removal system is installed, based on any of the following types of equipment:

- hydraulic wash or self-alloy;

- delta scraper or belt conveyor.

More often, farmers use a self-fusing system for cleaning the premises. To do this, pipes wrapped in slippery material with plugs are laid at an angle across the entire area of the barn, and when opened, manure flows into special tanks.

Self-alloying manure removal system is made of PVC pipes Ø 250 mm

Lighting in the barn

There are certain requirements for barn lighting that must be adhered to:

lighting standards - in the stalls 50 lux, in the feeding area - 75, in the entire barn - 200 lux and no more, otherwise production rates will decrease; It is necessary to use LED lamps, since fluorescent lamps emit low-intensity light when the standard temperature drops to 20–25 °C; When arranging lighting in the barn, it is important to correctly calculate the duration of daylight hours and smoothly change the lighting during this period - from 4.00–4.30 to 8.00–8.30 the illumination is increased, and from 16.00–16.30 to 20.00–20.30 it is gradually reduced.

For the normal development of animals in the barn, it is necessary to provide high-quality lighting - in daylight, cows give more milk, and calves eat better and grow faster

Barn ventilation

The increase in milk yield of cows is greatly influenced by the microclimate surrounding them, so the ventilation of the barn must be thought out to the smallest detail. During the summer heat, indoor air temperatures can be very high, which can affect a decrease in lactation, since at temperatures above 25 degrees there is a reduction in animal feed consumption.

Figure 6. Popular ventilation systems

Also, the high temperature inside affects additional energy consumption to release excess heat, which causes a decrease in milk yield.

The arrangement of ventilation systems has the following positive aspects when keeping cows:

- Fast payback for ventilation

- Reducing the potential for heat stress in animals

- Limited flock agitation indoors

- Improved air flow into the room and air circulation

- Increasing the volume of milk produced

Approximate ventilation diagrams for a barn are shown in Figure 6. To store hay and straw on a household plot, it is necessary to build a barn made of boards. Such a barn can accommodate an annual supply of roughage (hay) per cow of about 3 tons, as well as winter straw - 1 ton, used as bedding. In addition, hay and straw can be stored in a stack under a canopy on four poles.

Construction

Pouring the foundation

When designing and building a barn, keep in mind that you will need to pour the foundation, and for this you need to use only high-strength materials that can withstand heavy weight. Typically, baked bricks are used for this, which are laid with cement bricks. Concrete is also successfully used in the construction of barns.

Walling

In order for all animals to feel comfortable and cozy, the walls must be warm and dry. Adobe brick is suitable for this. It is made from clay, sand and straw. Thanks to the use of such material, animals can easily survive the winter. The wall below should be lined with standard red brick, which can be combined with shell rock if desired. Thanks to the high porosity of the materials, heat will be retained for as long as possible. Red brick has a number of advantages - long service life, fire resistance, strength and frost resistance. You can also use cinder block during construction.

To retain heat as long as possible, a masonry of 1.5 bricks is enough. The walls can also be plastered and then whitewashed, so that when light is reflected, the room appears even brighter.

Barn floor

The barn design standards clearly include a clause on floors. This is a very important stage, since the floor must be highly durable, warm and not harm the health of the cattle. The ideal option is to build a floor with a coating that will not allow water to pass through.

Remember that the floors in the barn must be insulated, otherwise the animals may develop mastitis, which is fraught. The ideal covering is wood, but due to rot it is short-lived and does not withstand loads well. Most often they make a cement or concrete floor, and, of course, insulate it. For insulation, you can use straw or sawdust. But such bedding will need to be changed frequently for hygiene reasons.

Stock

For a barn of any size, the problem of a well-equipped drain is urgent, which will prevent excrement from accumulating in the room. To do this, you will need to lay the floors on a slope. A special groove should be equipped at the very bottom, thanks to which waste will flow into the pipe. Remember that the issue of hygiene is very important in such a place, otherwise there will be a risk of infections, and this is a threat to the lives of livestock and losses.

Stall

Now let's look at what to consider when designing and building a barn, and in particular a barn for them. It should be comfortable and separate for each animal. In order for the cow to get enough food, the feeder should be about 8 liters in volume - so it can fit the amount of straw or hay. Like the rest of the elements, you can build the stall yourself. The standard dimensions of the feeder are 0.8 m wide, 0.65 m high, and 1 m long.

Usually the feeder is made of pine or oak boards. Before building the feeder, it is necessary to clean the boards, dry them and sand them so that the animals do not accidentally get hurt or get a splinter.

There are 3 types of such designs:

- Lifting.

- Folding.

- Movable.

Lifting models are the most convenient, since thanks to their design features they are easy to wash, disinfect, and do not require much effort. Another good option is a feeder with a grid. The length of the grid should be equal to the length of the feeder and be inclined at 45 degrees. This way the food will not be scattered and trampled everywhere.

Ventilation options

At the moment, there are 4 main ventilation options that can be used in cattle housing:

- Natural ventilation is the simplest option, where air exchange is carried out thanks to ventilation shafts and openings that are available in the building.

- Forced ventilation - works thanks to tunnel and circular fans, as well as thanks to valves.

- Ventilation curtains are a combination of synthetic fabrics or plastic that creates a fence for a barn. If you want to ventilate the room, the curtains can be raised using a mechanism or manually.

- Light-aeration ridges are a special polycarbonate structure that covers the opening of the structure. With the help of this “ridge” you can ensure good air flow and increase illumination.

The choice depends on your wishes and budget.

Construction of a cowshed

The selected version of the mini-farm and barn project needs to be studied and, if necessary, slightly modified. This will help tailor proposed projects to specific conditions.

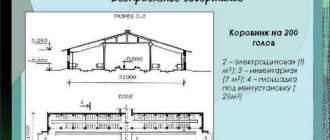

A brick cattle structure must be built on a solid foundation. A lightweight version can be made for frame, wooden or block walls. The roof is made 2-slope with a high ridge. On top there is a hayloft and a storage system for the necessary inventory, equipment, etc. Another option is a modern hangar-type barn with an arched roof. The profile for it is gradually increased to the required size.

The ceiling of a cattle shed is usually made of thick boards. For cold regions, double decking is required. Sealing joints is done using clay. To maintain heat, you need to pour sand or sawdust. Layer thickness - at least 10 cm.

What is a barn

A cowshed (regardless of size) is a capital structure in which the full cycle of keeping cattle (cows, bulls, calves) is carried out. This includes both a barn for one cow and farms for cattle. If in a private barn the problem is carefully caring for the animal to obtain milk and meat for their own food, then the construction of cattle farms is intended to provide income, and therefore includes elements of industrial livestock breeding.

In a barn, with proper organization, full-fledged livestock breeding is carried out, which means obtaining offspring (calves), raising young animals, feeding and caring for adult animals. Depending on the type of cattle (meat or dairy), maximum product yield must be ensured: optimal and quick fattening or productive milking. These indicators largely depend on how the cattle farm was built and how the care of the cows was organized.

How to properly set up a new barn? The health of animals and their productivity depend on the solution to this issue. The construction of barns is a very responsible, labor-intensive and costly undertaking that must take into account sanitary standards, hygiene rules, technical and fire safety requirements. It can only be carried out according to a professionally developed functional project, after carefully selecting a site for buildings and obtaining all the necessary permits.

Of course, you can build a small barn for cows with your own hands without unnecessary paperwork and approvals, but such a building must still meet all the requirements. Otherwise, it will simply not be possible to ensure the normal development of the animal, not to mention obtaining high milk yields. N

Project requirements

When building a barn with your own hands for 10 heads, it is important to comply with all the general requirements for such premises. It is important that the barn meets the following considerations:

- environmental friendliness;

- strength;

- tightness;

- ergonomics and others.

In addition, the building needs to fit harmoniously into the surrounding landscape. And it is necessary to carefully calculate all costs before starting construction in order to provide for all needs and expenses.

In a barn for 10 heads, it is necessary to provide a small compartment for calves. Since the total livestock is not too large, an area of 3x4 meters will be quite sufficient for calves.

But how to make a cage from a mesh for rabbits, and what materials can be used, is indicated here.

The video shows the barn project:

You need to think about equipping the building with ventilation and sewerage. In a small barn, you don’t have to make a conveyor for mechanical waste removal, but clean it manually. In this way, it will be possible to avoid the costs of conveyor equipment and its maintenance.

It is important to insulate the premises: cows must be in a warm building, otherwise constant colds and illnesses will affect the overall milk yield. The temperature inside should be about +10: in winter it is permissible to lower it to +4 degrees, and in summer it can rise to +20 degrees. Such conditions provide optimal comfort for cows: animals feel great at the indicated temperature, do not spend a lot of energy on heating, directing it to the formation of milk and the growth of meat.

It is important to make the walls in the barn warm and durable. In addition, they, of course, should not allow moisture from the street to pass through. The floor surface should also be dry, level and warm. In addition, it should be convenient to remove waste from the floor. If you choose durable but cold concrete for the floor, be sure to cover it on top with wooden boards or boardwalk so that the animal does not freeze.

Barn option for 10 heads

When calculating the required area of a barn, we proceed from the following standards: a minimum of 20 m2 is required for one cow, 10 m2 for a calf, and 12 m2 for a bull. Guided by these standards, you can easily calculate the size of the barn to build. However, experts advise constructing a building with reserves to allow for a possible expansion of the livestock.

Pay special attention to the foundation. Since cows are large and heavy animals, the foundation of the building must be weighty, strong and reliable. It is best to use concrete or baked brick for its construction. But what types of garage designs with a utility block there are, and what they look like, can be seen in the photo.

Construction stages

The construction of any barn, even a small one, takes place in several stages:

- Building design

- Laying the foundation

- Walling

- Roof of the room

- Flooring

- Organization of ventilation and lighting

- Arrangement of the barn

The construction project is carried out taking into account a number of factors: comfort, environmental safety and financial efficiency.

After drawing up the project, they begin to lay the foundation, which can be monolithic, strip or columnar. The type of base depends on the material of the walls. So, for the construction of a brick shed it is better to use a monolithic foundation, and for a wooden one - a columnar one.

The construction of a monolithic foundation includes:

- Digging a trench, 50-70 cm deep;

- Installation of formwork with reinforcement;

- Laying a cushion of crushed stone or sand;

- Pouring concrete mortar;

- Waterproofing the dried surface using roofing felt or roofing felt.

A columnar foundation is built in a similar way, but the foundation pillars are poured into forms with reinforcement, insulated with roofing felt. The distance between such pillars should be no more than two meters.

For any type of foundation, waterproofing and the presence of a water ramp are mandatory. Therefore, the outer edge of the foundation must be covered with a sand-crushed stone layer, and the base itself must have a waterproofing slope.

The construction of walls begins on a protected foundation made of materials that retain heat well. It can be either wood or brick (regular red or adobe). Wooden walls are warmer than brick walls, but their service life is quite limited. Although brick walls require additional insulation, they provide good ventilation. Adobe brick retains heat well and ensures dryness in the room. Foam block and sand-lime brick are excellent for building a large barn and do not require large material costs, but a wooden structure will cost more.

Experts recommend covering a small shed with a gable roof, which is not only more stable, but also retains heat due to the attic. In addition, the attic serves as an excellent hay storage all year round. The version of a shed without an attic is easier to build. In this case, boards are tightly laid under the roofing material (slate or roofing felt), the joints of which are sealed with clay mortar. The surface of the boards is covered with a layer of insulation (dried sawdust, slag, dry soil) up to 10 cm thick. Slate or roofing material is used as roofing material, which are laid so that water does not flow under the eaves.

An important condition for a properly built barn is a comfortable floor. In other words, it must be waterproof, warm and easy to clean. The most optimal material for the floor is called baked brick, which is more durable than wood and not as cold as concrete. The concrete floor must be covered with bedding (wooden panels) to prevent the animals from freezing and getting sick. Laying the floors is preceded by compacting the soil and laying a layer of roofing felt or slag. The floors themselves should be located 10 cm above the ground level. You should also provide a slight slope of the floor (a difference of 2 cm per 1 linear meter) for the natural drainage of waste into the gutter.

In order for pets to feel comfortable and please their owners with high milk yields, it is necessary to take care of ventilation and lighting levels. The ventilation system can be built independently in the form of an exhaust pipe with a special damper or a box made of boards (15x15 cm). The outlet of the ventilation system is located above the level of the roof ridge. Windows can also be used to ventilate the room. However, in this case, it is necessary to ensure that the animals are not exposed to drafts.

The required level of lighting is achieved through windows, which must be located at least 100 cm from the floor so that the cow cannot catch them with her horns. The optimal window area is 10 times less than the window area. In addition, it is recommended to plaster and whitewash the interior of the barn to accumulate sunlight.

Figure 4. Interior arrangement of the barn

Arrangement of a barn involves the installation of feeders and drinkers, both group and individual, as well as the organization of a paddock for walking. Such a walking area is usually located outside the building. In this case, the total length of the walking path for each cow must be at least 500 m. The area itself must be fenced and covered with a canopy.

Farm arrangement

Premises requirements

The barn should be such that there is at least 10 square meters for each individual. m. At the planning stage, care should be taken to ensure that the room can be easily cleaned.

It is best to build from brick, but other materials can be used. Keep in mind that the room must have good ventilation, but a draft is very dangerous for animals.

Air temperature – not lower than 8 °C. To clean the air from ammonia and other gases, ash, which is scattered on the floor, is well suited. If you keep more than 10 individuals, then you need to install an automatic supply of water and food into the room, and if there are fewer individuals, then make sure that the animals can always access feeders and drinkers (but do not place them on the floor, it is advisable that they be on 8-10 cm raised).

Purchase of livestock

It is best to buy calves from special farms or breeders. When choosing individuals, pay attention to weight and age. Buy calves that are already feeding on feed and grass on their own, this way you will save a lot of money and time on feeding.

It is best to take six-month-old bulls; they have just finished feeding on milk and have already received their first vaccinations. Make a purchase in the spring, when the first grass appears, then the calves can be released for a walk. In addition, at this time of year, their weak young body is not so susceptible to various diseases, and fresh greens on the pasture will help to avoid many digestive problems.

When choosing bulls, you need to pay attention to several indicators:

- Is the calf's weight normal for its breed?

- physique, presence of defects, level of development;

- information about parents - mother's productivity and father's weight.

What to make a floor for a cow in a barn from

When choosing a material for construction, you should pay attention to its ability to retain heat, absorb or repel moisture, and ability to withstand loads

Equally important is the raw material used in the manufacture of the material: how toxic it is, and whether its fumes will harm the cows

The advantages of a wooden covering are its environmental friendliness and the fact that it retains heat well. Otherwise, wood is not recommended for flooring, since it quickly absorbs moisture and odors; this property accelerates the aging process of wood and its rotting. The tree may not support the weight of the herd; in addition, dozens of hooves will leave indentations on it, and subsequently the animal may trip here and be injured. Wood is difficult to disinfect and clean from feces, so the material also loses in terms of barn hygiene.

Cement or concrete

There are conflicting opinions regarding concrete and cement:

- on the one hand, the material is durable and strong, does not allow moisture to pass through, and is easy to clean, wash, and disinfect;

- on the other hand, concrete is cold, such a floor will provoke diseases in animals, in particular, mastitis in heifers, reducing their productivity.

However, after weighing the pros and cons, most farmers use concrete. The lack of heat is compensated with the help of warm bedding, for example, livestock mats.

Burnt brick

Brick is made from clay, which is then fired for strength, producing hollow and solid bricks without voids.

Among the advantages of the material:

- environmental friendliness;

- sound insulation;

- thermal insulation;

- fire resistance;

- resistance to corrosion and fungi.

The main disadvantage is considered to be the high cost compared to other materials; in addition, brick is not able to withstand heavy loads. The hooves will leave cracks and gouges, which over time will begin to let in moisture. Brick is more suitable for the walls of the structure.

Samana (unburnt)

The peculiarity of adobe is that clay and straw are used in its production. To give it completeness, it is not fired, but dried in the sun. The product is completely natural. Advantages of adobe:

- low cost;

- heat and sound insulation;

- fire resistance;

- hygroscopicity.

Minuses:

- protection from dampness in the form of plaster is required;

- the material is susceptible to fungi and insects;

- questionable frost resistance in harsh winter conditions.

The table shows the performance characteristics of the described materials:

Financial plan

The payback period for investments after opening a farm for fattening bulls is about 2 years. Its duration is influenced by many factors:

- initial investment volume;

- the presence of a land plot owned by the investor;

- percentage of loss of young animals during fattening.

Fattening bulls for meat will be a successful business if you correctly calculate the amount of investments and current expenses and try not to go beyond these limits.

Investments in the project

Let's consider how much money it will take to open a small farm in the countryside:

- purchase of a small plot of land – 30,000;

- construction of a corral - 130,000;

- purchase of equipment – 100,000;

- purchase of 20 calves – 250,000.

The total investment amount is 510,000 rubles.

Current expenses

Monthly expenses include:

- expenses for feed for calves – 30,000;

- salary for two employees – 30,000;

- other expenses – 5,000.

Total: 65,000 rubles per month.

Calculation of profit and payback period of the project

Bulls are fattened until they are 14–16 months old, that is, for a year after purchase. Further keeping of animals is inappropriate. For 10 months of fattening, the farm owner will spend 650 thousand rubles. At the time of slaughter, the weight of the bull is 700 kg. Wholesale buyers offer 90–100 rubles for 1 kg of beef. Considering that the slaughter yield of meat from a carcass is 65%, the farmer will earn about 50 thousand rubles from the sale of each of them.

A livestock of 20 bull calves, under favorable circumstances, will bring the entrepreneur 1 million rubles a year after opening the farm . Investments in the project will fully pay off after 2 years of work.

Breeding bulls for meat is a profitable business. Its advantage is that you can start with a minimum amount of investment, buying 2-3 calves, or with a large capital. For those who live in the village and are familiar with the specifics of cattle breeding, this is a great idea with prospects for expansion.