What is the device?

A milking machine is a special device that is used for milking cows. In small farms, mobile household models are used, and in large livestock complexes, industrial (with automatic control) stationary units are used.

Despite the variety, milk is taken from the cow by each product under the influence of vacuum (rarefaction). The device consists of a vacuum unit and milking equipment. During milking, cows may be in stalls or in pens that use different patterns (parallel, radial, series). The simplest milking machine is equipped with the following elements:

- glasses (4 pieces);

- milk and air ducts;

- cans for collecting milk;

- motor, pump, manifold, pulsator.

Node purpose:

- glasses (plastic or metal) with rubber tubes inside - devices for attaching the udder to the teats and milking;

- milk lines - hoses connected to each glass serve to suck out milk;

- pipelines - hoses connected to each glass serve to supply vacuum;

- vacuum unit (electric motor, pump) - designed to create a rarefaction of air (vacuum) necessary for the milking process;

- pulsator - a valve for alternately supplying air and vacuum into the pulsation chamber of the milking cup;

- collector - for distributing vacuum among glasses and collecting milk.

Manufacturers produce milking equipment with different operating principles. For example, two-stroke and three-stroke. The two-stroke device usually works on the principle of compression and suction of milk. The three-stroke system is easier to tolerate by animals, and it has an additional rest mode.

In simple machines, milk is collected in cans; in industrial installations, milk flows through milk pipelines into special tanks.

The heart of every milking machine is a motor that rotates a vacuum pump that creates a constant vacuum. Under the influence of vacuum passing through pipelines and atmospheric air, milk is sucked out. To create a variable vacuum from a constant vacuum, a pulsator is used. Each element included in the device ultimately serves to suck milk from the cow's udder.

What types of milking machines are there?

To understand which milking machine is right for your farm, you need to understand what the main differences and similarities between milking machines are. Any milking system is equipped with:

- Milking cups.

Most often they consist of a metal body and an elastic rubber or silicone liner called nipple rubber. On one hanging unit there are four milking cups, each of which is put on the cow's teats and participates in the release of milk from the udder. - Milk and vacuum lines.

These hoses are made from non-toxic material. Their main task is to supply vacuum and transport milk. - Can.

Milking buckets are made from aluminum, plastic or stainless steel. Milking machine cans can hold from 25 to 40 liters of milk. - Collector, pulsator and pump.

These are the main mechanisms in the design. The operation of the entire milking machine depends on their condition. Their main task is to create pulsating air pressure, thanks to which milking is carried out.

Two-stroke and three-stroke systems

The first milking machines operated on a push-pull system. Milking took place by squeezing and unclenching the nipples with rubber inserts. If you milk a cow with a push-pull milking machine, she will experience discomfort. Today there are still push-pull milking machines. They are used on small farms.

The three-stroke milking system works on the suck-squeeze-rest principle. This way, the cow's teat is not overstrained or injured. The cow produces more milk and feels much better.

Industrial and domestic milking machines

All milking devices can be divided into industrial and household. For personal use, they use household devices that have good maneuverability and are small in size.

Industrial milking machines are connected to large stationary milk collection tanks. These installations are equipped with automatic control, allowing you to select an individual mode for each individual. Such systems are not maneuverable and are installed in special rooms - milking parlors. The use of such equipment is justified when keeping a herd of more than 50 dairy cows.

Motor type

There are only two types of motors:

- Dry.

The dry type of motor is considered more environmentally friendly, easier to operate and maintain. However, this type of motor does not tolerate dampness particularly well. It is noisy and can overheat under heavy load. - Oil.

The oil type motor is characterized by quiet operation. The oil-powered machine does not disturb the cows. However, it requires more attention. It is necessary to monitor the oil level in the engine, monitor the condition of the components and carry out regular maintenance. Good manufacturers produce do-it-yourself kits and offer detailed instructions for servicing milking machines.

Principle of operation

How the technology works:

- the installation operates from the mains;

- a vacuum unit creates a rarefaction of air (vacuum);

- in the process of creating a vacuum, an electric motor and a pump are involved;

- the muffler reduces the noise level during operation of the unit;

- the vacuum regulator maintains the required pressure in the system;

- inside the pipeline the air pressure becomes lower than the external (atmospheric) pressure;

- the pulsator converts constant vacuum pressure into alternating pressure;

- air is pumped into the collector with a pulsation frequency of 45-65 cycles per minute;

- each pulsation consists of a contraction and relaxation cycle;

- vacuum pressure is supplied to the milking cup placed on the nipples;

- thanks to the pulsator, the rubber inside the glass is relaxed and compressed;

- the milk flows through the milk line into the can;

- Depending on the type of device, cattle can be milked in stalls or pens.

See also

How to learn how to milk a cow by hand correctly for beginners for the first timeRead

A vacuum pump pumps out air to create a vacuum. The pressure inside the pipeline decreases. The vacuum activates the pulsator. The compression of the rubber inside the milking cups depends on this element of the milking machine. Ultimately, the cups of milking equipment work (milk milk) thanks to the pulsator and the alternate supply of ordinary air and rarefied vacuum into the pulsation chamber. The selected milk flows through the milk line into the can.

How to milk a cow correctly?

The milking technique is not complicated, but it requires following a number of rules every time you start working. First, the cow is prepared - calmed down, examined and the udder is prepared: washed, disinfected, wiped dry (including the belly around the udder, hind legs).

Find out what to do if a cow produces little milk.

Step-by-step processing technique:

- Prepare a slightly warm solution of water and laundry soap.

- Rinse the udder with this solution.

- Rinse with water.

- Disinfect with an antiseptic.

- Dry the nipples with a towel or napkins.

- Use your hands to massage the udder.

- Start milking.

After milking, immediately disinfect the udder and wash the milking unit.

By machine

Preparing the udder for work is universal for both automated and manual milking. Everything needs to be done quickly - no more than a minute should pass between the end of the treatment and putting on the device. The glasses are connected one by one, after which the installation is turned on, the settings are checked and the start button is turned on.

The system collects vacuum for about 5–7 minutes. There is a vacuum gauge to check its pressure. The operating pressure of each device may differ slightly, see the data sheet. This is approximately 50 kPa. If the indicator is higher, it should be adjusted.

Video: Milking a cow with a milking machine

Working with the mounted units is simple: all 4 glasses are lowered down, the manifold valve is pressed, the vacuum is filled and it is ready for work. The milk hose is clamped with your fingers or a special clothespin. The glasses are placed on the nipples strictly vertically. The glass filled with vacuum automatically grabs the nipple, which you first direct inside. After the pinch is removed from the hose, the process automatically begins and lasts about 8 minutes.

Did you know? The composition of milk obtained from the same cow may not be the same. This is due to the fact that the udder shares are not connected to each other.

The tubes of the milking machine are transparent, so you can easily monitor the process and stop it when milk collection stops. It is important to milk the rest completely. Upon completion of milking, press the manifold valve, wait 2 minutes for the pressure to normalize and remove the glasses. If you forcefully tighten them, you will cause pain to the cow and injure the teats.

We recommend reading: Type of productivity, how much meat can produce

Manually

After finishing the udder treatment, as recommended above, take your time and proceed to hand milking carefully - cows are quite sensitive and shy. When approaching an individual, try to be in its field of vision. Hands are washed, disinfected and dry.

Manual massage is required; it lasts 30 seconds until milk is released from the udder. After the massage, slightly lift the udder with your hand and push it, imitating the movement of a calf.

Important! Milk the first 3 streams of milk into a separate mug covered with clean gauze. This way you can detect diseases in a timely manner.

There are two ways of manual milking - pinch and fist. Which one is more convenient is up to everyone to choose for themselves.

Pinch (with two fingers)

This method is best used for heifers with short teats. Milking is gentle, using fingertips. The technique is not complicated: pinch the nipple in its upper part with two fingers - thumb and forefinger, move your fingers down, squeezing milk into a bucket or other prepared container. The pinch is often painful for cows, so be careful. Don't overstretch your nipples or you will tear the muscle tissue.

The front lobes are milked first, then the rear lobes. Alternate pairs: milk the first ones a little, start with the second ones, return to the first ones. Movements must be made smooth, unhurried, gradually accelerating. You cannot interrupt, even if you are very tired.

Milk everything without any residue to avoid the development of mastitis and help increase milk yield in the future. Afterwards, treat the nipples and wipe dry with a clean cloth. If this is not done, microscopic cracks may form on them, which is painful and causes bacteria to multiply.

Fist (five fingers)

Milking technique: grasp the nipple with five fingers at once, the index finger under the thumb, the little finger outside the end of the nipple. The latter should be smooth, and milk should not flow down your hands. Consistently, the nipples are compressed from top to bottom. Only your fingers work, don’t move your brush. The fist unclenches without leaving the nipple so that a new portion of milk flows to the latter.

Milking a cow with a “fist”: a - the fingers are weakened, the milk enters the cavity of the nipple; b - the thumb and index fingers block the udder tank and the nipple cavity, the reverse flow of milk from the nipple into the udder is impossible; c - other fingers alternately (from top to bottom) squeeze the nipple and milk out milk. Milking with a fist is characterized by the fact that the milk stream flows continuously. The anterior lobes should be removed first, followed by the posterior lobes. Completion of the procedure is standard - rinse, disinfect, wipe the udder.

Advantages and disadvantages

Advantages and disadvantages

saving time, reducing labor costs;

milking speed increases (cattle are milked in 4-6 minutes);

completely milks milk from the udder;

does not cause pain in cattle;

the milking process takes place under sterile conditions;

You can master working with the equipment yourself using the instructions;

it is advisable to use with any number of cattle;

the cost of the device pays off in just a month (when milking milk for sale).

a certain amount of money is required for the purchase;

Cattle will have to be accustomed to machine milking;

Equipment sometimes breaks down and requires repair.

Types of milking machines

All machines for machine milking of cattle are classified depending on the structure and constituent elements. The simpler the technology, the lower its cost.

By motor and pump type

The following types of vacuum units (pump type) are used in milking machines:

- membrane (budget option for 1-3 cows);

- rotary (reliable, silent);

- centrifugal (expensive);

- piston (powerful, noisy).

By type of milking

Based on the principle of operation (type of milking), the following installations are distinguished:

- two-stroke - suction stroke and compression stroke (high speed);

- three-stroke - the cycle of sucking, squeezing and resting (meets the physiological needs of animals);

- four-stroke - squeeze-suck, squeeze-rest (more gentle mode and low milking speed).

By purpose of application

Types of equipment depending on purpose (conditions of use):

- stationary for milking cattle in stalls, milking parlors, on conveyor lines;

- mobile (carried manually or using a trolley) for individual milking.

Types of equipment depending on the type of animal:

- for milking cows (4 glasses);

- for milking goats (2 cups).

Preparing for milking

Before milking a cow using a machine or manually, it is necessary to prepare the udder. It is cleaned of dirt, washed, disinfected and dried. In milking parlors, there are special passages for cleaning the udder, where the legs, belly and udder of animals are washed.

In private farms, the udder is treated as follows:

- prepare a warm soap solution: dilute water with laundry soap;

- wash the udder;

- rinse with clean water;

- wipe with sodium hypochlorite or other antiseptic;

- the nipples are dried with a disposable towel;

- Milking cups are placed on dry teats.

The operator's hands must be clean. To improve milk production and to ensure that the cow produces it better, an udder massage is performed. Knead all 4 lobes of the mammary gland. The procedure is especially important for heifers and for cows with high milk production. Residues of milk can become stale and cause mastitis.

The operator carefully examines the udder, checking it for mastitis or cracks. If no pathologies are found, then milking begins. The first drops of milk are expressed into a separate cup. Inspect the liquid. If it contains curd flakes or blood clots, the animal is examined by a veterinarian. You cannot milk a cow with a machine. In this case, the manual method is used. It is necessary to milk the animal. Otherwise, pathological changes will occur in the mammary gland, which will cause pain in the cow.

After calving, cows are milked every 3 hours. This will increase lactation. After six months they switch to morning and evening milking. It is better to collect milk at the same time so that the animal’s body gets used to full milk production.

Before milking, it is necessary to check the operation of the equipment. If the device operates with a hissing sound, the pump is leaking air. The installation is turned off and the fault is eliminated. A ringing sound indicates a problem with the motor or pump. If the pump is oil, then moving parts may need lubrication.

More on the topic: Methods and types of artificial insemination of cows

Popular models

Common stationary installations:

- “Tandem” - serves 50-250 cows standing sideways in individual pens;

- “Herringbone” - serves 150-600 heads, animals stand in a row (at an angle) in separate sections;

- “Parallel” - serves 500-1200 heads, cows stand in separate sections, with their backs to the machine.

Popular portable models and their characteristics:

- “Volga” (three-stroke) - a device with two-chamber glasses, an improved pulsator and a vacuum pump;

- “Burenka” (two-stroke) - lightweight and low-cost design, easy to use, has a rotary vacuum pump;

- “Berezka” (two-stroke) - a device with a rotary pump (designed to serve 12 cows);

- “AID” (two-stroke) - a design weighing 42 kg, with a vacuum pump, pulsator, designed to serve 7 cows.

Device selection criteria

Owners of one cow or a small herd can buy a budget portable milking machine for just $200. This is usually a two-stroke piston unit. Three-stroke devices using a vacuum rotary pump are considered more expensive. For a large herd under stationary milking conditions, a special automatic milking unit is installed in the barn, allowing 50 or more cows to be milked simultaneously.

See also

Anatomy of the structure of the cow skeleton, names of bones and internal organsRead

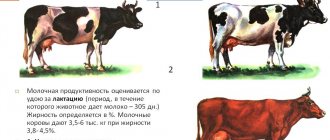

How many times a day should a cow be milked?

The amount of milk produced per day depends on the cow, its productivity, feeding, and health. But the animal should be milked at least twice a day. The optimal amount is three, but they switch to a three-time regimen only if the cow produces a high milk yield.

If you do not milk a cow or milk less than she needs individually, the milk will flow out spontaneously. This leads to inflammation of the udder and its hardening.

Important! It is important for cows to be milked every three hours after calving to help improve lactation. They switch to twice-daily milking after six months.

If you milk your cow three times a day, but she produces less than 10 liters of milk or no more, switch her to twice a day.

It is important to observe the animal, take into account its personal characteristics, maintain the same intervals between milking and handle it at the same time of day.

We recommend reading: Where do they prefer to live and eat?

Assembly and installation of the device

If the milking equipment is powered by an electric motor, then, first of all, you need to connect an outlet to the milking place on the farm. It is advisable to choose a dry place, protected from moisture. Before milking, you need to connect all the elements of the milking machine using the instructions or operating manual for the specific model.

Equipment ready for operation must have all vacuum and milk hoses connected to their connectors. The device is turned on by pressing the “Start” button. Before use, it is recommended to adjust the pressure in the system using a vacuum regulator. You can put your finger in the milking cup and feel the pulsation of the rubber. It is recommended to wash the machine before using it for milk collection.