Definition of the concept

First, let’s talk about what is meant by milk quality. This concept constitutes a general set of properties, namely:

- color;

- smell;

- consistency.

Additionally, requirements may be presented to:

- fat content;

- acidity;

- usefulness;

- safety.

The definition is also based on consumer properties. This refers to the ability of a product to satisfy the needs of the buyer.

Quality may be characterized as poor, good or excellent, depending on the class, grade, category or grade corresponding to various requirements.

Who controls in Russia?

Rospotrebnadzor, the federal service for supervision of consumer rights protection, which monitors the quality and safety of dairy products, is responsible for the inspection. We wrote about how the verification process is carried out in this article.

During inspections, the main violations are revealed:

- Failure to comply with storage conditions established by the manufacturer.

- Lack of shipping documents confirming the quality and origin of the products.

- Non-compliance of dairy products with the requirements of technical regulations for safety indicators.

- Incomplete and unreliable information about products pre-packaged in the absence of the consumer.

Actions are taken for all violations.

, a non-profit organization established by the government of the Russian Federation, also participates in milk inspections and its examination

The Russian “Quality Mark” can be assigned to a product for a period of 1 to 3 years. All this time, the manufacturer must maintain the quality of the product at a proven high level.

The Federal Service for Veterinary and Phytosanitary Surveillance (Rosselkhoznadzor) carries out supervision and control in the field of veterinary medicine and plant protection. Which directly affects the health of the animal, and as a result, the health of humans.

Formative factors

The composition and properties of milk can change under the influence of various factors influencing it. They depend on the stage of lactation of the cow. During this time, the properties of the liquid change three times.

In the first 5-7 days after calving, colostrum is released, which is very different from milk, which will happen after a longer second period, when it has a normal, more stable composition. The third period lasts 12-10 days before the cow is started. Colostrum contains many proteins - albumin and globulin.

- In the first batches, more protein and mineral salts are obtained than in subsequent yields of normal milk. Colostrum is thicker and has a color ranging from yellow to brown.

- In the subsequent, second period, the fat and protein content gradually increases, and later becomes close to the average value.

- Before milking stops, in the third period, the amount of fat, proteins and minerals in milk increases greatly, and milk sugar decreases. The taste of such milk will be bitter and salty.

Factories do not accept milk received 8-10 days before the start of the cow.

The fat content of the final product depends on the breed of the cow and ranges from 2.5 to 6%. Also, the quantity and content of fat depends on the living conditions of the animal, the quality and abundance of food. With good nutrition, the protein content in milk increases.

The quality of milk depends on:

- Stages of lactation.

- Cow breeds.

- Conditions for keeping animals.

- Type and volume of feed.

- Livestock health.

- Personal hygiene of farm workers.

- Attention to sterility in the room.

- Temperature, humidity and gas saturation of the environment.

- Calm environment or stress.

- Pasteurization and sterilization necessary to neutralize bacteria and microorganisms, followed by preparing milk for consumption.

Increased temperature and humidity negatively affect the productivity and composition of milk. The presence of noise and non-compliance with the daily routine also has a bad effect on the quantity and quality of milk.

Insufficient heat treatment leads to the presence of undesirable biochemical processes in milk and dairy products. The result may be a decrease in the quality, taste and nutritional value of the products.

Protein content of cow's milk

Milk protein is an important indicator of milk quality; modern genetics is aimed at increasing it. And to unlock the full potential of animals, including in obtaining high levels of protein in milk, is the task of production workers.

The protein content of milk reflects whether the cow is well supplied with energy and is a kind of energy barometer for the herd. The level of protein in milk depends on whether the rumen microbes that synthesize microbial protein have enough energy at their disposal. And only with high productivity, protein that is not broken down in the rumen becomes increasingly important. There is a noticeable relationship between animal condition curves and milk protein (Figure 2).

Figure 2. Body condition and protein content of milk in the first 100 days of lactation

Urea in milk is an indicator for checking the supply of rumen microorganisms with nitrogen, the basis of crude protein. A urea content below 15 mg/100 ml of milk indicates a significant nitrogen deficiency in the rumen. This limits the activity of rumen microorganisms, which reduces feed consumption and, as a result, milk production. The protein content of milk in the first two months of lactation changes in the same way as the animal’s body condition. Typically, in the first third of lactation, the protein level in milk decreases with increasing milk yield, since during this period energy is in short supply. During this period, protein above 3.1% is considered normal. But if it falls below 2.8%, this means that the animal no longer has energy reserves in the body. In any case, even with very high milk yields of more than 50 kg per day, the protein content in milk should not fall below 3.1%.

When the animal begins to gain weight again and its condition score increases, the protein level in the milk also increases, and milk yield decreases. In late lactation, milk protein levels of up to 3.8% are considered normal. A protein level above 3.8% signals a significant decrease in productivity. This development is closely related to fat accumulation. In late lactation, milk production is almost independent of body condition if it lies between scores of 3.0 to 3.5. At a higher condition, above a score of 3.5, you need to be prepared for a very sharp decline in productivity in combination with a very high protein value (more than 3.8%).

Product requirements

Milk supplied to enterprises must meet certain requirements to ensure that high-quality butter is obtained from it. Animals providing the product must be healthy and protected from infections.

Depending on organoleptic (color, consistency, taste and smell), physico-chemical (acidity, temperature, density, purity group) and microbiological (presence of bacteria and microorganisms) indicators, milk is divided into grades:

- Higher.

- First.

- Second.

- Unsorted milk.

Cow

Requirements for milk supplied for the production of butter are regulated by the current GOST R 52054-2003 “Natural cow’s milk - raw materials”. In addition to standard standards, special claims are made to milk: in terms of fat content and the chemical composition of milk fat.

In appearance it should be a homogeneous liquid without sediment. A product with high fat content should not have cream residue. The taste and smell must be pure. The color is white with a slightly yellowish, cream or bluish tint, depending on the type of milk.

There may be defects arising from the feed, incorrect processing technology, violation of the regimes and terms of its storage.

Vices can be:

- smell (bread, garlic, cheese);

- taste (sour, soapy, salty, unpleasant);

- colors (due to pigmenting bacteria);

- consistency (thick, slimy, viscous).

Goat

According to TU 9837-001-00495220-98 “Goat milk. Purchasing requirements”, the drink must be clean, without foreign tastes or odors. It appears to be a homogeneous liquid without flakes or sediment, not frozen. Color ranges from white to faint yellow.

Density of at least 1.027 g/cm3. The milk must be fresh and meet the requirements of veterinary and sanitary standards.

Goat milk has a large number of somatic cells in its composition. The acidity is 14. The fat content is not standardized because it is not used for making oil.

Sheep

Composition of sheep milk:

- water – 82.1%;

- fat – 6.7%;

- protein – 5.8%;

- sugar – 4.6%;

- ash substances – 0.8%.

Sheep milk has many beneficial properties, its protein is well digested in the body, and its calorie content is much higher than that of cow and goat milk.

- The first grade should be clean, sweetish, fresh, without foreign taste or smell.

- In the second, slightly perceptible acidity, mustiness, stall smell, and faint smell of feed are resolved.

Milk that does not meet the requirements of the first and second grades is not used in cheese making.

Comparison table.

| Whole milk, % | Sheep | Goat | Cow |

| Overall Density | 18,3 | 11,2 | 12,1 |

| Fat content | 6,7 | 3,9 | 3,5 |

| Squirrels | 5,8 | 2,9 | 3,4 |

| Lactose | 4,8 | 4,1 | 4,5 |

| Calorie content, per 100g. | 102 | 77 | 73 |

Cream

The cream necessary to create butter must comply with GOST “Cream-raw materials”.

Raw cream is divided into:

- raw cream;

- pasteurized cream.

Depending on organoleptic, physico-chemical and microbiological parameters, they are divided into varieties:

- higher;

- first;

- second.

Requirements for drinking cream:

- The taste and smell should be clean, with a noticeable aftertaste of pasteurization.

- The consistency is homogeneous, without stray lumps of fat and protein flakes.

- The color is white with a yellowish tint.

Cream with defects is not allowed for sale:

- bitter;

- rancid;

- feed flavors;

- viscous consistency.

We suggest studying the requirements for the quality of other products, including dumplings, meat, fish and seafood, honey, ice cream, drinking water, as well as vodka, beer and whiskey.

Table 1. Physico-chemical parameters of milk

| Type of milk | Fat content. %, not less | Content of dry fat-free residue, %, not less | Acidity, degrees, no more |

| Whole normalized | 3,2 | 8,1 | 21 |

| Refurbished | 2.5 | 8,1 | 21 |

| Increased fat content | 6,0 | 7,8 | 20 |

| Ghee | 6.0 | 7,8 | 21 |

| Protein | 2,5 | 10,5 | 25 |

| Low-fat | — | 8,1 | 21 |

| Ionite | 3,2-3,5 | 8,0 | 18 |

- According to bacteriological indicators, milk pasteurized in bottles and bags must meet the requirements of group A with the total number of bacteria in 1 ml of milk not exceeding 75,000 and the titer of E. coli 3 ml and group B, respectively, 150,000 and 0.3 ml, and pasteurized in flasks and tanks - 300,000 and 0.3 ml (see GOST R 520 90-2003).

Milk defects

Milk defects are caused by poor quality feed, microflora entering the milk, incorrect processing technology, violation of storage conditions and periods, and other reasons.

Consistency defects are caused by the activity of certain microorganisms.

-Milk acquires a thick consistency with the participation of lactic acid bacteria, and a slimy or viscous consistency - under the influence of mucus-forming bacteria.

-As a result of the development of E. coli bacteria, milk undergoes fermentation and foam forms.

-If bacteria that secrete rennet enter the milk, it curdles when heated, even at low acidity.

Odor defects are caused by specific odors of feed or unsanitary conditions of the premises in which animals are kept (stable, rotten, cheese, garlic, etc.)

Taste defects are the most common type of defects:

· milk acquires a sour taste as a result of the activity of lactic acid bacteria or Escherichia coli;

· rancid taste is formed in milk during long-term storage at low temperatures under the influence of lipase enzymes, and also appears in milk in the last days of lactation;

· bitter taste is due to the activity of putrefactive peptonizing bacteria in milk, and may be caused by the presence of wormwood in feed;

· unpleasant specific tastes can appear from the presence of nettles, garlic, onions, turnips, radishes, field mustard, etc. in the diet of animals;

· salty taste appears with some diseases of the udder;

· milk acquires a metallic taste as a result of the interaction of lactic acid with the metal of the container;

· a greasy taste occurs when milk is stored in the light as a result of the oxidation of milk fat by air oxygen;

· a smoky taste and smell are possible in sterilized milk and packages if the paper is burned when gluing the transverse seams of the package.

Color defects (redness, blueness and yellowing) appear under the influence of pigmenting bacteria. Sometimes yellowing of milk is associated with blood getting into the milk during milking due to the painful condition of the animal.

When milk freezes, its quality noticeably decreases: the colloidal state is disrupted, as a result of which the milk stratifies; Desalinated ice forms on the walls of the container, fat floats to the surface, and protein concentrates in the central and lower parts. When peeled, flakes and lumps form in the milk. The taste becomes watery and sweetish.

Colostrum milk obtained within seven days after calving does not withstand pasteurization, has high acidity and an increased content of albumin, globulin and salts. Cannot be processed.

Old milk , obtained within 7-10 days before milking stops, has a salty and rancid taste due to changes in the mineral composition and the presence of lipase. Butter made from such milk is unstable during storage, and the cheese is of poor quality. Old milk is not accepted.

Use in cooking. Milk has a wide range of uses in cooking: it is used in the preparation of first and second courses, as well as various sauces and additives that give the product a specific milk taste.

Storage, transportation, packaging and labeling. Milk is stored in well-ventilated and darkened rooms: pasteurized at a temperature of 0 to 8 ° C for no more than 36 hours from the end of the technological process; sterilized - from 1 to 10 °C for up to 6 months; from Odo 20 °C no more than 4 months.

Milk is transported in different types of containers: tanks, flasks, canisters, from which it is poured into bottles with a capacity of 0.25; 0.5; 1.0 l and in plastic bags, as well as in cardboard bags with special polymer coatings of various capacities; in refrigerated or isothermal means of transport, ensuring the maintenance of optimal air temperature and thereby the safety of the product.

The marking is applied to the milk packaging with indelible paint or embossing and includes the following information: name of the product, trademark of the manufacturer, volume in liters, deadline for sale, designation of the regulatory document, fat content in percentage.

The best in Russia according to Roskontrol rating 2021

What qualities should the best milk have, and by what parameters is it selected? Evaluation and identification of the best product is based on the following parameters: safety, naturalness, nutritional value, quality.

TOP-16, based on the Roskontrol rating and customer reviews:

- “Prostokvashino” selected, from 3.4% to 4.5% . Completely safe, does not contain vegetable fat and milk powder, without preservatives or antibiotics. In appearance, taste and smell it corresponds to the parameters. There are no disadvantages.

- “Vkusnoteevo” 3.2% pasteurized . Complies with GOST, good organoleptic properties, no vegetable fats or preservatives. Product without any comments.

- "Ekomilk" 3.2% pasteurized . Does not contain antibiotics, good organoleptic characteristics, fat and protein indicators correspond to the label. No flaws.

- “Selo Zelenoe” 3.2% ultra-pasteurized. It is possible to use phosphates, the mass fraction of fat does not correspond to the specified one. Otherwise, the advantages are the same.

- "Avida" 3.2% pasteurized. Small percentage of skimmed milk solids. Safe, without preservatives.

- "Valio" 3.2% UHT . Deviation from the specified protein proportion is not critical. Meets other requirements.

- "Parmalat" UHT 3.5%. Good organoleptic characteristics, safe.

- "Asenyevskaya Farm" 3.2% pasteurized . “Empty” taste, complaints about organoleptic characteristics. Complies with GOST, safe, without vegetable fats, the labeling is correct.

- “Red Price”, 3.2%, UHT . The mass fraction of fat does not correspond to the specified one; phosphates are used. The rest of the indicators are normal.

- "Ostankino" 3.2% ultra-pasteurized . Signs of boiling and a fodder taste were detected. Mostly compliant, safe.

- "Ruzskoe" 3.2-4% pasteurized . The only disadvantage is the high price.

- "Kremlevskoe" 3.2% . GOST 31450. Shelf life 10 days. Safe, consistency, color and smell are normal.

- “Mamulya” 3.2% ultra-pasteurized. Long shelf life and reduced naturalness. Otherwise everything meets the requirements.

- "House in the Village" 3.2% UHT. According to the criteria of the technical regulations, the name “milk” does not correspond: the mass fraction of protein is below the permissible level, even taking into account the error.

- "Piskarevskoye" 2.5 % Normal ogranoleptic indicators, safe.

- “36 kopecks”, 3.2%, ultra-pasteurized . Does not correspond to the name “milk”: the presence of phytosterols was found - a sign of added non-dairy fat.

Fat to protein ratio

The fat and protein levels in milk must be in a certain ratio to each other. A ratio of 1.1:1 to 1.5:1 indicates balanced feeding.

A fat to protein ratio of more than 1.5 , especially at the beginning of lactation (except for the colostrum period) is a warning signal. High fat content is a sign of very strong mobilization of fat from the body. Low protein content indicates a lack of energy, although some of the energy comes from the body's reserves. The consequence of this may be metabolic disorders (ketosis).

If the fat to protein ratio is greater than 1.5 throughout lactation, this indicates a structure-rich but energy-poor feeding. Especially with poor quality bulk feeds and a lack of concentrates. The consequence of this is low milk productivity and low protein content in milk

A very low fat to protein ratio (below 1.1) occurs with a diet that is high in energy and low in structure (lots of concentrates). In this case, it is necessary to correctly distribute the feed in accordance with productivity.

When interpreting the ratio of fat to protein in the first third of lactation, it is necessary to take into account that both the threat of ketosis (with a high indicator) and the threat of rumen acidosis (with a low indicator) are possible. In this case, the “normal” fat to protein ratio may be misleading. Therefore, careful monitoring of animals during this period is necessary, and perhaps even individual collection and analysis of data for animals up to the 30th day of lactation.

To identify feeding errors throughout the year, you can analyze the fat and protein levels of the collected milk monthly. For example, if fat and protein values decrease in early May, this may indicate that there was insufficient structure when transitioning to pasture or that the transition was made very abruptly.

Photo: Data from control milkings provide valuable information for monitoring animal nutrition and health and should be actively used by specialists in each enterprise.

How to determine quality characteristics?

It is important to buy good milk, but it is impossible to determine its advantages and disadvantages through the packaging. But you can do this after the purchase and never make a mistake again.

How to check at home?

There are several ways to determine the quality of milk at home:

- Soda . Add 1/2 teaspoon of soda to half a glass of milk. If foam appears, then the milk is not fresh.

- Boiling . If the milk begins to curdle when boiling, it is spoiled.

- Iodine . The starch content of a product can be detected by this chemical element. If the reaction is positive, the milk will have a bluish tint. Starch is added to milk to thicken it.

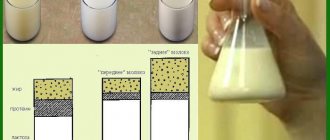

- Alcohol . It is used to determine the amount of water. You need to combine alcohol with milk in a 2:1 ratio, then shake for about 2 minutes. Pour into a cup and observe. If flakes form immediately, then there is no water. And if after some time, the drink is diluted.

We invite you to watch a video on how to check the quality of milk at home:

Organoleptic evaluation

This is a sensory assessment and is therefore subjective. A good fresh product should have a white color with a yellowish tint, a uniform liquid consistency, a pleasant smell and taste.

Method for organoleptic evaluation of smell and taste. Determined on a five-point scale, where 5 is excellent.

Veterinary and sanitary examination

Let us list the main requirements of veterinary and sanitary examination for raw milk and dairy products:

- Cow's milk should be a homogeneous liquid from white to slightly yellow in consistency, without sediment or flakes. Characteristic taste and smell. Fat content not less than 3.2%. Density 1.027-1.035 g/cm. Acidity in degrees Turner (°T) 16-20.

- Sheep meat is similar in parameters to cow meat, but may have a specific smell. Fat not less than 5%. Density 1.034-1.038 g/cm. Acidity no more than 24°T.

- Goat is also similar to cow's, but may have a goat's smell. White color. Fat content not less than 4.4%. Density 1.027-1.038 g/cm. Acidity no more than 15°T.

- Mares' milk has a sweetish taste with a specific odor. White, with a bluish tint. Fat content not less than 1%. Density 1.029-1.033 g/cm. Acidity no more than 7°T.

- In buffaloes , in appearance and consistency, it is a viscous, white, odorless liquid. Fat content 7-8%. Density 1.028-1.030 g/cm. Acidity 17-19°T.

Devices, somatic cell analyzers

For analysis use:

- Cryoscope - to determine the freezing point.

- Milk analyzer - to determine the content of fat, protein, skimmed milk solids (SMR), density, temperature.

- Butyrometers - measure fat volume.

- Hydrometers - determine temperature and density.

- A viscometric analyzer is a device for quickly determining one of the parameters of milk quality: somatic cells, which makes it possible to identify diseases of cows on dairy farms, dairies, reception points, and breeding farms.

Requirements for fermented milk products

- Kefir . It can be fatty, low-fat or fruity, depending on the fat content. The taste, color, and consistency are homogeneous, similar to liquid sour cream. Gas formation in the form of individual bubbles and no more than 2% of separated serum is possible.

- Cottage cheese . Cottage cheese of the highest grade has a pure, fermented milk taste and smell, without foreign tastes and odors, and a heterogeneous structure is allowed. The color is white, slightly yellowish, with a cream tint. In the 1st grade, light aftertaste of feed is allowed, the presence of minimal bitterness. The consistency is loose, spreadable, and for low-fat cottage cheese - with a slight release of whey, crumbly.

About the quality of milk powder

Powdered milk

is a white powder obtained by drying pasteurized normalized cow's milk. In the production of high-quality powdered milk, no extraneous additives are added; in terms of the composition of proteins and fats, it is only slightly inferior to fresh natural milk; carbohydrates and minerals are completely preserved in it.

Powdered milk 158 g

Powdered milk production

High quality milk powder

is obtained as follows: natural whole milk “from under the cow” is normalized and pasteurized, then, using modern equipment, the resulting product is condensed and homogenized, after which the drying process begins, during which the liquid contained in raw milk is gradually removed, and all useful the constituent parts are concentrated.

There are several ways to dry milk - using vacuum units, spray or roller devices. Depending on the drying method, the appearance and color of the milk may vary slightly. The powder obtained after drying is sifted, gradually cooled and packaged.

Powdered milk quality control

High quality milk powder

has the following organoleptic characteristics in accordance with the requirements of GOST R 52791-2007 “Canned milk products. Powdered milk. Technical specifications":

Appearance – fine powder or powder consisting of single and agglomerated particles of milk powder. A small number of lumps are allowed, which crumble under slight mechanical stress.

Color – white, white with a light cream tint.

The taste and smell are characteristic of pasteurized skim or whole milk without any foreign tastes or odors. The taste and smell of boiled milk is allowed.

How to reconstitute milk powder?

High quality milk powder

It easily turns into a healthy and tasty drink; to do this, just dissolve it in warm water (38-45 ° C). To obtain 1 glass of reconstituted milk with a fat content of 2.5%, you need to mix 5 teaspoons (25 g) of dry milk and 200 ml of warm water. High-quality powdered milk does not immediately dissolve in water due to its high content of natural protein, but if dissolution occurs quickly and without lumps, most likely the powder contains vegetable fats. When diluting high-quality powdered milk, you must first add a small amount of warm water to the dry powder and mix thoroughly, and then, stirring constantly, pour in the remaining water and let the drink brew for several minutes to completely restore the protein.

In appearance, reconstituted milk does not differ from pasteurized milk and has a pronounced milky taste, characteristic of pasteurized milk. A high-quality drink has a milky, opaque color and, when stirred, leaves an even white milky trace on the walls of the container, without grainy sediment from dyes and foreign impurities and without fatty oily inclusions.

Another important quality indicator of milk powder is acidity. It is determined by a laboratory method and, according to the requirements of GOST R 52791-2007, ranges from 16 to 21 units.

The most important advantage of powdered milk is that it can be stored much longer than fresh milk; with a low moisture content, the development of pathogenic microorganisms does not occur: in sealed, opaque packaging, the shelf life is 12 months.

Also, powdered milk has more stable characteristics and a balanced composition, which reduces the risk of allergic reactions in young children and allows the development of food recipes with greater accuracy.

Powdered milk is widely used for the production of: reconstituted milk, baby food, confectionery production, in the dairy and fat-and-oil industries, in the production of bakery products, as an additive to meat or sausage products, as well as in cosmetology for the production of creams, face masks, etc. d.

Since June 12, 2008, in the territory of the Russian Federation, Federal Law No. 88-FZ introduced the Technical Regulations for Milk and Dairy Products, which strictly regulate the name of the product, requirements for the quality and safety of milk powder. The Federal Compliance Mark on the label looks like this: