Design of cattle farms

Before designing and building cattle farms , you need to decide on the following:

- select a plot of land (when designing in the general plan, cowsheds with transition galleries to a milking parlor or slaughterhouse, a hayloft, a grain warehouse, a summer range, and other auxiliary hangars will be located on the site)

- find connection points to utilities (connection to electricity, water, and preferably to sewerage is required; the main thing, of course, is water, since this is a watering place for animals and sanitation for the farm, so a well or borehole will not work)

- decide on the type of cattle farm being designed (meat, dairy, combined, breeding farm)

- select the type of housing on the cattle farm (barn: tethered or loose housing)

- and finally you need to decide on the livestock. (standard barn designs are usually designed for 50, 100, 200, 400, 800 and 2000 heads and have a two, four or six row stall arrangement system)

To achieve high profitability when breeding cattle, it is necessary to optimize every component of the process: selection of equipment, herd, number of jobs, construction. It is necessary to optimize, since the quality and low cost of imported meat, grown with the latest technology, even taking into account the dollar exchange rate and import duties, is clamping down on the market. All issues regarding investment in the construction of barns and the cost of rearing are resolved at the design stage. However, the choice of the designer and supplier of the main building structures must be treated very carefully, since the cost of building a cattle farm usually takes up to 75% of the budget, versus 25% for equipment. We recommend the following sequence of actions:

- prepare a request with a description of barns (a prefabricated building for housing cows or bulls has the largest area of all cattle farm facilities), indicate in it the necessary dimensions, row layout (two, four or six rows), type of housing (the design depends on this), region of construction ,

- send it to several organizations engaged in the design and production of complete prefabricated buildings for cowsheds and livestock complexes (sending it to more than 3-5 organizations is pointless, since the market for light metal structures and LSTK is quite tight),

- compare the cost, if there is a small difference in price, choose as a contractor an organization that performs all the work on the design and construction of turnkey barns. Our organization provides the best price guarantee - this means that if you have a commercial offer that is more attractive in your opinion, then you can send it to us, and we will point out the differences or offer a completely similar one, but on more favorable terms.

Why do they trust us?

Full-fledged meat processing plants and modular slaughterhouses for cattle and pigs operate successfully throughout Russia. Our Customers are small, medium and large livestock enterprises, farmers, factories.

Customers value us for our flexibility, thoughtfulness of all solutions, and the optimal choice of equipment for slaughter from leading industry manufacturers. By purchasing a slaughterhouse created by our engineers, you will receive for free:

- loading onto your transport or delivery to the railway station;

- trial period of operation under the supervision of specialists;

- consumables for the commissioning period;

- package of documents for approval by supervisory authorities;

- detailed instructions for the operation of slaughter equipment or a modular building as a whole;

- object passport;

- assistance in enterprise branding.

We provide installation of equipment for slaughterhouses of cattle and pigs and subsequent service at a competitive price.

Construction of cowsheds and cattle farms

The construction of cattle farms begins with the selection of a design solution and the construction of hangars for keeping animals (cowsheds). The cost of the project depends on the choice of design solution. If you calculate the cost of building a turnkey cattle farm, then the difference in the choice between a frame of variable cross-section and a cattle farm made from light steel frames can be 3-5%. When built from reinforced concrete or laminated wooden beams, the price of a cattle farm will be 10-15% higher. Metal structures also have the following advantages: firstly, they are more mobile and suitable for subsequent modernization, since all connections are made with bolts; secondly, galvanized metal structures (LGSF) have a high degree of protection against corrosion, and in the case of variable-section frames they can be treated with polymer compounds such as Prime Platinum AGRO (or analogues), which provide protection for 10 years or more. In addition, the purchase of a complete, prefabricated turnkey barn building will relieve the Customer of many worries and solve those problems that agricultural producers, as a rule, do not understand anything about. Our company has standard projects for 50, 100, 200, 400 and 800 heads, which you can familiarize yourself with and choose the appropriate option. If such a proposal is not found in our arsenal, then the Customer will be offered the design and construction of a barn according to an individual project, taking into account his preferences.

When choosing between renovation and new construction, you should always lean towards new construction. This is due to the following considerations: the existing stock of real estate is so dilapidated that it is necessary to spend almost the same money on its reconstruction as on new construction; modern barns made of LSTK meet new requirements and allow cattle to be raised with greater profitability.

- Provide a favorable microclimate

- Allows you to maintain cleanliness

- Maximizes the necessary ventilation requirements

- Protect cows from hypothermia and overheating

Let’s also say a few words about frameless hangars, which are sometimes also used for barns, but at the same time have several disadvantages.

Firstly, the cost of such a hangar is significantly lower than a barn made of LSTK, only if we are considering cold buildings. If a frameless building needs to be insulated, then its cost becomes comparable to the construction of a cattle farm from LSTK, since when insulating a frameless building, another sheet of metal appears, and polyurethane foam is used for insulation, the cost of which is per 1 cubic meter. is about 5,000 rubles, while the cost of basalt wool (even on a foil and reinforced base) does not exceed 2,500 rubles. for the same volume. Both with tethered and loose housing, it is necessary to insulate the barn building, since in the summer the roof gets very hot and the animals become stuffy, they lose a lot of moisture, as a result of which weight and milk yield are reduced, and if you use a modern watering system, then insulation of the barn is necessary, to avoid freezing of pipelines.

Secondly, and this is the most significant difference, when designing free-stall barns, you can include in the design a natural ventilation system consisting of roller blinds and a light ventilation lantern. Frameless buildings do not have windows and this is a global disadvantage.

Farms and cattle complexes

Farms and cattle complexes are built taking into account the natural, climatic and economic conditions of the country's regions, the direction of livestock farming, the specialization of farms, the provision of food supply, the size of the livestock and animal housing systems.

In cattle breeding, animals are classified into the following age groups, taking into account their physiological state:

— sires aged 1.5 years and older;

— dairy cows and with suckling calves, dry (pregnant), deep-calving (the last two weeks before calving) and fresh-calving (the first two weeks after calving);

- heifers - pregnant heifers;

— calves of dairy and combined breeds under the age of 20 days (preventive period) and from 10 days to 6 months, as well as calves of meat breeds under the age of 8 months;

— young animals of dairy and combined breeds aged from 4 to 18 months. and meat breeds - up to 18 months.

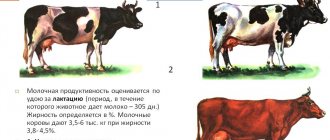

On dairy farms and complexes, complex mechanization and partial automation of production processes are used. For this purpose, production flow lines are created.

By flow-technological line (PTL) we mean a set of machines and equipment located in a certain sequence and interconnected in terms of productivity, ensuring the execution of the production process according to flow-intermittent and cyclic schedules. Integrated mechanization is a level of mechanization in which machines and mechanisms continuously perform all the main and auxiliary production processes. The level of mechanization refers to the percentage ratio of the number of animals served by machines to the total number of animals on the farm.

The placement of individual premises of the farm (complex) and the technological connection between them must be such as to ensure the rational organization of work and the correct flow of technological processes, depending on the livestock keeping system and the purpose of the buildings.

When keeping livestock in stalls (tethered), a multi-row placement of stalls is used, with every two rows connected by a common feed or manure passage. No more than 50 stalls are allowed in one continuous row.

When keeping livestock loose, buildings are partitioned into sections for separate housing of groups of animals, taking into account productivity, lactation period and physiological state. No more than 80 boxes are allowed in one continuous row.

The maternity ward on a dairy farm (complex) must be divided into two sections by a continuous partition; in one of them there is a room for calving cows, in the other - a dispensary for calves. Calving areas are equipped with stalls 1.5 m wide for deep-calving cows and 1.2 m wide for fresh-calving cows. In the maternity ward, stalls are set up for calving cows. The dimensions of the stalls are 3 x 3 m, and their number is 4...5% of the total number of places in the maternity ward, or 1...1.5% of the number of cows on the farm. In the dispensary, individual cages for calves are placed in rows. In one room of the calf barn, group cages are installed for calves aged from 10 days to 4 months and from 3 to 6 months.

With any housing system, livestock enterprises provide walking areas (Table 1).

Table 1

Norms of area, m2, walking areas for one animal

| Groups of animals | Walking area |

| hard surface | without hard coating |

| Cows and heifers for 2…3 months. pre-calving on dairy farms | |

| Young animals of all ages and heifers up to 6…7 months of age. | |

| Young and mature cattle in a feedlot | 15…20 |

| Calves aged 10 days | |

| Beef cows with calves aged up to 7...8 months. |

When keeping livestock in groups, an average area of the premises is provided for one animal, m2: for a cow - 4...5, young animals - 2...3, calves up to 3 months of age - 1...2, calves aged 3...6 months. (in boxes) - 1.5, cows and heifers in a stall - 1.7...2.3.

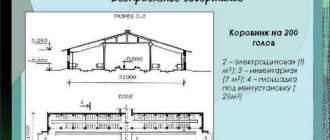

Cowsheds are built for 200 and 400 heads.

In the case of tethered housing, each animal is kept in a separate stall, equipped with a tether, a feeder, an automatic drinking bowl, and means for mechanizing feed distribution, manure removal and milking. Stall dimensions, m: width - 1...1.2, depth - 1.7...1.9. With a mobile feed distribution system, the width of the feed passage is taken to be 2.2...2.3 m. The width of the manure passage between the wall and the row of stalls should be 1.5 m (at least), and between the rows of stalls - 2 m (at least).

With a four-row arrangement of stalls, the width of the barn building is taken to be 18 m (using stationary feed dispensers) and 21 m (using mobile feed dispensers). Barns 18 m wide are usually built as single-span barns without internal columns. Premises 21 m wide are built with one or three bays (the width of the outer bays is 7.5 m, the middle one is 6 m).

Cowsheds for free-stall housing of livestock are designed and built with a capacity of up to 400 heads (Fig. 1). The premises are partitioned off with partitions into sections for separate keeping of different groups of animals. Each section provides access to a walking or feeding yard. Animals are kept on deep bedding that is changed once a year. When keeping livestock without bedding, sections are equipped with individual boxes.

A box is a place for an animal to rest, limited on the sides by dividers and in front by a partition or wall. Horizontal stops are attached to the top of the box dividers, which are located at the level of the back of the cow's head. The width of the box is chosen so that the cow cannot turn around in it, as a result of which most of the floor of the box is not contaminated with manure. To prevent contamination from the manure passage from getting into the box, resting areas for cows are arranged on a hill (15...20 cm) and with a slight slope towards the manure passage.

There are two types of boxes: only for resting animals and combined – for resting and feeding. The length of the box is 190...210 cm, width -100...110 cm. Combined boxes are suitable only when the animals are fed and kept in the same room. The length of such a box is 155...180 cm. A fencing grille is placed in the front part of any box. Combined boxes are equipped with drinking bowls; the floors of such boxes are provided with slits and manure grates. Rows of boxes are located along and across the room.

Fig.1. Barn for 400 tethered cows (all dimensions are given in meters):

1 —

stalls;

2 -

rooms for fans;

5 — vestibules; 4 -

manure passages;

5 — manure removal system collectors; 6

- electrical panels;

7 — manure removal channels; 8 -

aft passages

Calf barns are usually built for 200 heads, combining them with a maternity ward. Calves aged up to 10...14 days are kept in individual cages in an isolated dispensary for up to 2 months. — in group pens for 4...6 heads and older than 2 months. in group pens for 10…15 heads. In group cages, an area of 1.1...1.5 m2 should be provided for one animal.

Intensive technology for beef production with a full (completed) cycle provides for the cultivation, rearing and fattening of young cattle aged from 15...20 days to 15...18 months. on specialized industrial farms and complexes, as well as the sale to the state of animals weighing 420...450 kg. These complexes use pasture and non-pasture keeping of animals, both with and without walking, as well as keeping them in open areas.

In beef production technology, two main directions for obtaining meat have emerged: from specialized meat breeds and from dairy and meat-dairy animals. The technology provides for the continuity of the process of growing and fattening young animals according to a cyclic schedule. Calves aged from 10...20 days to 3...4 months. kept without walking and loose on slatted floors or on a leash in boxes. Rearing and fattening are carried out indoors or in open or semi-open areas. In enclosed spaces, livestock are kept tied or loose on slatted solid floors in groups of 20...50 heads, and on platforms - 100...200 heads.

Figure 2 shows a complex for raising 10 thousand heads of young cattle per year.

Feedlots (Fig. 3) are intended for fattening young animals and culled adult cattle. These sites are built mainly in the southern regions of the country with an estimated outside air temperature in winter not lower than -20 °C. The site area is divided into a livestock keeping area and a feed storage and preparation area. In the animal keeping area, sheds or light indoor premises with a capacity of no more than 250 animals with sections for different groups of young animals and walking areas (pen) equipped with feeders and drinking bowls are arranged. The dimensions of sheds for young animals are built at the rate of 3 m2 per head when animals are kept on deep bedding and 2 m2 when they are kept on slatted floors. When constructing pens with a hard surface, an area of 5 m2 should be provided for the animal, without a hard surface - 15...20 m2.

Fig.2. Complex for raising and fattening 10 thousand heads of young cattle per year (all dimensions are given in meters):

A -

pavilion development (standard project 819-215);

b -

development with enlarged buildings (standard project 801-376);

1 -

calf barns for 720 heads each (22 x 84 m);

2 -

connecting galleries;

3 —

building for receiving calves;

4 -

buildings for young animals for 720 heads each (22 x 84 m);

5

- feed preparation room with feed storage;

6 -

sanitary slaughter station;

7

- boiler room;

8 —

building for loading livestock;

9 — maintenance point; 10 —

veterinary and sanitary checkpoint;

11 -

calf sheds for 1000 heads each (84x96 m);

12 —

truck scales;

13 -

hay barn;

14 -

calf barn for 4000 heads (84x96 m);

15 -

buildings for young animals for 4000 heads each (84 x 120 m);

16 —

block for disinfection of vehicles (6 x 135 m);

17

— room for pumps (pump room);

18 -

manure storage

Fig.3. Area for fattening young animals (all dimensions are given in meters):

A

— master plan diagram;

b -

canopy for the feeder;

1 -

calf barns for 400 heads each (18 x 86 m);

2 -

platform for roughage;

3 -

silo trench;

4 -

feed shop and concentrated feed warehouse;

5 — sheds for resting animals; 6 —

canopies over the feeders;

7

- treatment areas;

8 –

settling ponds (110 x380 m).

During the first period of fattening, animals are kept under a canopy, in the second - without canopies. To protect animals from winds and snow drifts, the sheds are covered on three sides with a continuous fence made of wood or asbestos-cement sheets. For the same purposes, part of the fence (usually on the north side) is made in the form of solid fences with a height of 2.7...3 m. To drain surface water, the paddock areas are made with a slope, due to which the water flows into settling ponds located behind the fence of the territory .

Cowsheds for tethered and free-stall animals

For effective maintenance, it is necessary that the frame design of a prefabricated barn building ensures:

1. ventilation inside the building;

2. took into account the technology of keeping (tethered or loose);

3. ensured long service life in aggressive environments.

Our company cooperates with equipment manufacturers such as Big Dutchman, De Laval, GEA, etc. This allows us to jointly design, manufacture and construct barns, dairy farms and cattle keeping complexes.

| Tether barn | Freestall barn |