Milk separator

There are ready-made options produced by well-established manufacturers, as well as devices that you can assemble yourself.

Purpose of the separator

Milk separators are represented by a centrifuge, where, under the influence of centrifugal force, various impurities are removed through separation. Cream separators have similar design characteristics , but the presence of holes in the conical disks allows cream to be separated.

Principle of operation

All separators have a similar design and, accordingly, approximately the same action, which is based on the following principles:

- milk is supplied from above and directed through a hollow channel to a disk riser, during the rotation of which the milk is dispersed. The centrifugal cleaning option, due to the different densities of milk particles and foreign impurities, allows clogging to be thrown onto the walls of the rotating drum, after which they settle on the inner surface of the body and are removed;

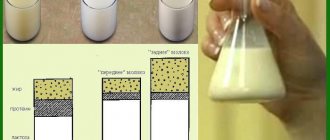

- conical discs with holes allow milk to rise to the top, and the presence of a small gap guarantees separation into fractions under the influence of centrifugal forces and gravity. Fat milk globules are combined into a single fraction, which allows you to separate the cream from the lighter fraction of milk and skim milk.

The most popular electric version of such equipment. If milk separators are equipped with a manual drive, then in order to obtain a high drum rotation frequency, multipliers are used.

Manual separator: operating principle (video)

The main elements of milk separators are as follows:

- drum;

- drive mechanism;

- bed or bowl;

- receiving-output device.

The main working part in any device for this purpose is the drum, which both cleans the milk and separates the cream.

How to choose

Choosing a quality unit on your own is not too difficult. There are only five main criteria for choosing a milk separator, but it is very important to treat them with due attention. To make the right choice, you need to pay attention to the following parameters:

- device manufacturer. Domestic manufacturers have proven themselves best. It is not recommended to purchase products from little-known Chinese manufacturers;

- the material used to make the body and drum. The least reliable are models with a large number of plastic parts and elements;

- diameter and dimensions of the separator drum, which must be at least 110 mm. It is this parameter that has a direct impact on the fat content of the resulting cream, as well as the speed of milk processing;

- quality characteristics of the internal motor, since in case of unstable voltage the best result is shown by a valve motor with an electronic control type;

- availability of a guarantee and the ability to purchase spare parts if necessary.

Among other things, the indicators of drum rotation frequency, the total number of drum disks, the ability to adjust the ratio of fat fraction and skim milk, and the fat content level of skim milk are of no small importance.

Types and models

A home or farm separator can be represented by several types and models, which have significant differences in many respects.

| Parameter | View |

| Purpose | To get the cream |

| To obtain high fat cream | |

| Cleaning from mechanical impurities | |

| Normalization by fat content | |

| Cleaning from bacteria and microorganisms | |

| Universal | |

| Curd dehydration | |

| Serum lightening | |

| Obtaining protein dust | |

| Homogenization | |

| Type of shell | Open option |

| Semi-closed option | |

| Sealed closed processing option | |

| Drive design features | Manual |

| Combined | |

| Electric | |

| Frequency of sediment removal | Systematic manual cleaning when the machine is stopped |

| Systematic centrifugal cleaning | |

| Continuous cleaning while the device is running | |

| Constant centrifugal through nozzles |

The most popular household models:

The most convenient and durable, according to domestic consumers, are the manual models “Krynka-100” and “RZ-OPS”.

Milk separator: overview of types and DIY production

A milk separator is a mechanical or electromechanical device for purifying milk or separating it, that is, separating it into different fractions. You can assemble such a device with your own hands.

Milk separator

There are ready-made options produced by well-established manufacturers, as well as devices that you can assemble yourself.

Purpose of the separator

Milk separators are represented by a centrifuge, where, under the influence of centrifugal force, various impurities are removed through separation. Cream separators have similar design characteristics , but the presence of holes in the conical disks allows cream to be separated.

Principle of operation

All separators have a similar design and, accordingly, approximately the same action, which is based on the following principles:

- milk is supplied from above and directed through a hollow channel to a disk riser, during the rotation of which the milk is dispersed. The centrifugal cleaning option, due to the different densities of milk particles and foreign impurities, allows clogging to be thrown onto the walls of the rotating drum, after which they settle on the inner surface of the body and are removed;

- conical discs with holes allow milk to rise to the top, and the presence of a small gap guarantees separation into fractions under the influence of centrifugal forces and gravity. Fat milk globules are combined into a single fraction, which allows you to separate the cream from the lighter fraction of milk and skim milk.

The most popular electric version of such equipment. If milk separators are equipped with a manual drive, then in order to obtain a high drum rotation frequency, multipliers are used.

Manual separator: operating principle (video)

The main elements of milk separators are as follows:

- drum;

- drive mechanism;

- bed or bowl;

- receiving-output device.

The main working part in any device for this purpose is the drum, which both cleans the milk and separates the cream.

How to choose

Choosing a quality unit on your own is not too difficult. There are only five main criteria for choosing a milk separator, but it is very important to treat them with due attention. To make the right choice, you need to pay attention to the following parameters:

- device manufacturer. Domestic manufacturers have proven themselves best. It is not recommended to purchase products from little-known Chinese manufacturers;

- the material used to make the body and drum. The least reliable are models with a large number of plastic parts and elements;

- diameter and dimensions of the separator drum, which must be at least 110 mm. It is this parameter that has a direct impact on the fat content of the resulting cream, as well as the speed of milk processing;

- quality characteristics of the internal motor, since in case of unstable voltage the best result is shown by a valve motor with an electronic control type;

- availability of a guarantee and the ability to purchase spare parts if necessary.

Among other things, the indicators of drum rotation frequency, the total number of drum disks, the ability to adjust the ratio of fat fraction and skim milk, and the fat content level of skim milk are of no small importance.

Types and models

A home or farm separator can be represented by several types and models, which have significant differences in many respects.

| Parameter | View |

| Purpose | To get the cream |

| To obtain high fat cream | |

| Cleaning from mechanical impurities | |

| Normalization by fat content | |

| Cleaning from bacteria and microorganisms | |

| Universal | |

| Curd dehydration | |

| Serum lightening | |

| Obtaining protein dust | |

| Homogenization | |

| Type of shell | Open option |

| Semi-closed option | |

| Sealed closed processing option | |

| Drive design features | Manual |

| Combined | |

| Electric | |

| Frequency of sediment removal | Systematic manual cleaning when the machine is stopped |

| Systematic centrifugal cleaning | |

| Continuous cleaning while the device is running | |

| Constant centrifugal through nozzles |

The most popular household models:

- "Rotor";

- "Firework";

- "ESB-2" and "ESB 2-04";

- "Neptune" and "Neptune-M";

- "Siberia-2";

- “Farmer S-01” and “Farmer S-02”;

- "Motor Sich";

- "Falcon";

- "Om" and "Om-3";

- "Ural-M".

The most convenient and durable, according to domestic consumers, are the manual models “Krynka-100” and “RZ-OPS”.

Manual milk separator

It is important to remember that milk separators can be electric or manual. The manual apparatus operates with direct physical participation . The bowl must be untwisted using a special handle that transmits accelerated rotation through a special drive.

There are three holes inside the bowl for draining cream.

Most often, hand-held equipment is made of plastic, which makes it lighter and more affordable . Metal devices are more durable and reliable.

Certain advantages of manual equipment include the absence of an electric motor and the possibility of use in the absence of electricity.

Electric milk separator

An electric separator is most often made of metal, but when choosing such equipment you need a competent choice of a reliable motor. Modern household milk separators are capable of:

- structuring milk by breaking it down into individual components;

- skimming milk;

- separation of cream of a certain degree of fat content;

- purification of the product from harmful impurities and bacteria hazardous to health.

The process of cleaning and creating dairy products using such equipment takes much less time and requires minimal attention.

How to adjust the thickness of cream

The operating principle of the cream separator is as follows:

- pouring milk into the drum of the machine through a funnel;

- installation of a clean container for receiving cream under the outlet socket;

- connecting the device to the network or mechanically twisting the handle.

The cream fat content can be adjusted directly during operation of the milk separator using the drum speed regulator. The adjustment part is located on the front panel of the electric drive. Turning the knob to the right allows you to increase the fat content of the cream. When rotating to the left, the mass fraction of fat decreases.

Making a milk separator with your own hands

A homemade apparatus for separating milk can be assembled quite easily with your own hands. The standard design includes a bowl for pouring milk and a motor that can spin it. The productivity of self-made equipment is quite low.

Due to the fact that such factory-made equipment is quite affordable and is represented by a large number of models, there is no need to manufacture such a device yourself. In addition, the purchase of material for manufacturing and the need to purchase tools makes doing it yourself costly, and also not very popular and in demand in our country.

How to make a separator with your own hands (video)

Of course, milk contains a large amount of useful substances, vitamins and minerals, but in order to get the most pure and healthy product, it is recommended to use high-quality and properly selected milk separators and cream separators.

:

Loading…

Source: https://DachaDecor.ru/dachnie-pitomtsi/separator-dlya-moloka-obzor-vidov-i-printsip-izgotovleniya-svoimi-rukami

Manual milk separator

It is important to remember that milk separators can be electric or manual. The manual apparatus operates with direct physical participation . The bowl must be untwisted using a special handle that transmits accelerated rotation through a special drive.

There are three holes inside the bowl for draining cream. Most often, hand-held equipment is made of plastic, which makes it lighter and more affordable . Metal devices are more durable and reliable. Certain advantages of manual equipment include the absence of an electric motor and the possibility of use in the absence of electricity.

How to choose a separator

Before choosing a separator, the buyer needs to familiarize himself with the technical characteristics and capabilities of the unit. It is better to choose such an item in a regular store, rather than online.

When choosing a household milk separator, customers pay attention to the price, design, dimensions of the milk receiver (bowl) and the performance of the device

The receiving bowl, parts and separator housing can be plastic and metal (steel and aluminum).

From a hygiene point of view, metal parts are better washed from milk residues, microorganisms are less retained on them, and, if necessary, they can be cleaned using any harsh detergents. Buyers often choose separators with plastic parts solely for reasons of economy rather than hygiene. Plastic models are cheaper.

Separators operate from a 220V network; many models can withstand significant voltage surges in the network (from 160 to 240 V). The weight of most household separators ranges from 3.5 – 5.5 kg.

Milk receivers in household models can have different capacities, most often the bowl volume is 5-5.5 liters. The throughput of the unit can vary between 60-80 liters of milk per hour. In some models of separators produced in recent decades, you can use a special screw to adjust the fat content of the resulting cream and skim milk.

Most often, the adjustable ratio is in the range - 1:10 - 1. 4. When using all, especially electric, separators, milk should be heated to a temperature of 40 - 45 degrees; warm fresh milk can be separated immediately after milking.

In manual separators, the circular movement of milk is created by rotating the handle at the bottom of the device. In some cases, the buyer makes a choice in favor of a manual separator. The price of such a device is a quarter less than the price of a separator with an electric motor.

If the device will be used in remote areas, where electrical networks are unreliable and there are voltage fluctuations, it is better to choose a manual model. The capacity of the receiving bowl for both types of separators is the same, and the performance of a manual device is not much less than that of an electric one.

If the separator is rarely used, you should not spend money on purchasing an expensive metal model; an economical plastic version will suffice. The more milk a farm produces, the more productivity your separator should have.

A good separator with a stable running engine is a guarantee of obtaining cream of the required quality. Therefore, the money invested in the purchase of this device will more than pay off - in a good mood, a feeling of satisfaction from the fact that the family receives tasty and healthy products, and the farmstead is bringing more and more profit.

Electric milk separator

An electric separator is most often made of metal, but when choosing such equipment you need a competent choice of a reliable motor. Modern household milk separators are capable of:

- structuring milk by breaking it down into individual components;

- skimming milk;

- separation of cream of a certain degree of fat content;

- purification of the product from harmful impurities and bacteria hazardous to health.

The process of cleaning and creating dairy products using such equipment takes much less time and requires minimal attention.

WHY DO YOU NEED A MILK SEPARATOR?

| Did you know that you can make many dairy products yourself? Cream, kefir, fermented baked milk, cottage cheese, cheese, sour cream, butter, yogurt, yogurt and even ice cream - all this can be prepared at home. All you need for this is farm milk (natural milk can be bought on the market) and a household separator: Buy. |

Preparing your own dairy products has many advantages: firstly, you get a natural and tasty product, and secondly, you have complete control over the entire preparation process and can be confident in the quality of the resulting products. Homemade cream, sour cream and cottage cheese do not contain any preservatives or chemical dyes, thickeners or other additives that are harmful to the adult body and absolutely unacceptable for children.

How to adjust the thickness of cream

The operating principle of the cream separator is as follows:

- pouring milk into the drum of the machine through a funnel;

- installation of a clean container for receiving cream under the outlet socket;

- connecting the device to the network or mechanically twisting the handle.

The cream fat content can be adjusted directly during operation of the milk separator using the drum speed regulator. The adjustment part is located on the front panel of the electric drive. Turning the knob to the right allows you to increase the fat content of the cream. When rotating to the left, the mass fraction of fat decreases.

Making a milk separator with your own hands

A homemade apparatus for separating milk can be assembled quite easily with your own hands. The standard design includes a bowl for pouring milk and a motor that can spin it. The productivity of self-made equipment is quite low.

Due to the fact that such factory-made equipment is quite affordable and is represented by a large number of models, there is no need to manufacture such a device yourself. In addition, the purchase of material for manufacturing and the need to purchase tools makes doing it yourself costly, and also not very popular and in demand in our country.

WHY IS IT PROFITABLE TO USE A SEPARATOR?

For example, let’s look at what can be obtained from 10 liters of milk (at the rate of 1 liter of milk = 1 kg).

When separating milk we get:

- 2 liters of cream;

- 8 liters of skim milk.

You can leave the cream as is, or you can make butter from it. As a result, from the cream we get:

- 0.5-0.8 kg of butter (beat by hand or using a butter churn: Buy);

- 1.2-1.5 kg buttermilk.

Buttermilk is useful for making pancakes, muffins, and pastries. You can also cook porridge with buttermilk, add it to smoothies, or use it to make diet milk drinks.

If you want to make cottage cheese, then from the remaining 8 liters of skim milk you will get:

- 2 kg of cottage cheese;

- 6 kg whey.

Whey is drunk in its pure form to improve digestion, improve immunity and lower cholesterol. Whey is also used to prepare milk and fruit cocktails. And, of course, whey is indispensable for cosmetic purposes.

As a result, from 10 liters of milk you will get cream, butter, cottage cheese, buttermilk and whey. And you cook all this yourself, with only milk and a couple of utensils on hand!

How to make a separator with your own hands (video)

Of course, milk contains a large amount of useful substances, vitamins and minerals, but in order to get the most pure and healthy product, it is recommended to use high-quality and properly selected milk separators and cream separators.

Experienced farmers know that it is not always possible to sell or sell fresh milk. Often there is a need to degrease it. Or make sour cream, cottage cheese or cheese from sour milk. Typically, these foods may take a day or more to prepare. A milk separator will help you cope with these tasks in just one hour.

If you are breeding cows, sheep or goats, milk separation equipment will be useful to you in any case, regardless of the size of the herd. Thus, you will increase the efficiency of your enterprise and, accordingly, will receive greater profits. Even if you don’t have a farm and you just want to pamper your family with fresh and high-quality dairy products, a milk separator will also come in handy.

Features of separation in the dairy industry

Milk separation is an important processing step. During the process, the product is split into fatty and fat-free components. This type of processing also provides mechanical removal of contaminants. There are no changes in the chemical composition of the separated fractions.

Qualitative factors influencing separation:

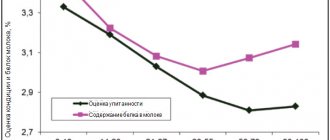

- If the liquid is thick, the quality of the resulting product will decrease. The degree of thickness is reduced by heating the milk. The quality of the process is also affected by the difference in the densities of the liquid being processed. It also increases with heat.

- If the milk is fatty, the separation process slows down. This is due to the fact that fat is heavier than the aqueous medium. The performance of the separator decreases. Inside the device there is a package of so-called plates (for cleaning) - the separation speed can be improved by increasing their number.

- The slowdown in separation is affected by incorrect technological processes used in the industrial pumping of milk. Rough pumps cause fat particles to become irregularly shaped. When they are round, separation is easier. The process is faster with larger particles. If they are small, then separation slows down.

The main feature that influences a good result is the temperature of the starting product. According to the instructions for household separators, the optimal mode is 35-45 degrees.

At higher temperatures, the efficiency of fat breakdown is better, but there are some minor nuances. To improve separation, it is enough to heat the liquid to 45 degrees. At higher temperatures the fat yield will deteriorate.

READ ALSO: Salt cucumbers with vodka for the winter

High-temperature separation mode is used in industries with heating up to 60-80 degrees. At the same time, the quality indicators of the equipment used are improved. The disadvantages of high temperature mode are as follows:

- cream getting into the return stream;

- the appearance of foam;

- splitting of fat globules into small parts.

Due to the separation of cold milk, the productivity of the equipment decreases. Other disadvantages of low temperature mode:

- partial crystallization of fat;

- increasing the viscosity of cream.

Design and principle of operation of the separator

The separator consists of a cylindrical drum, a plate separator, a set of conical disks (plates), a shaft, three receivers for milk, cream and skim milk, a housing, a chamber with a float, a reflector, a plug, a bushing and a support. Equipment for milk separation is divided into manual and electric. Unlike a manual separator, an electric separator is equipped with an electric motor, therefore, accordingly, it works using electricity. This is their main difference.

A milk separator is a device that allows you to separate the fatty fractions of milk from its liquid part. The operating principle of a milk separator is as follows: under the influence of centrifugal force, the main part of the milk is beaten to the walls of the equipment, and the cream is beaten to the center. As a result of separation, we obtain pure skim milk (skimmed milk) and cream. For example, if you want to separate six liters of milk, you will get five liters of pure milk and one liter of cream. That is, the ratio of parts is one to five.

Using the separator you can prepare cream, butter, cottage cheese, yogurt and fermented milk drinks.

DIY milk separator. What is dairy processing based on?

Fresh cow's milk is a suspension in which fat globules, called cream, are mixed with the heavier molecules of the rest of the milk.

They are easily separated from the bulk of the product by floating. To speed up the separation of fractions, milk separators have been created. Subsequently, the heavy residue is separated into curd mass and whey, but this is after ripening. There are also separators to separate them. You can separate the cream during separation in any percentage. If the final result of processing is 1:10, it means that for every 10 liters of skim milk, 1 liter of cream is obtained from 11 liters of milk. This is cream containing a large amount of butter and little liquid fraction. But you can get 3 liters of cream for 8 liters of skim milk. Such cream will be liquid and little butter will be obtained from it. The separator allows you to create a ratio from 1:4 to 1:12.

In everyday life and for the primary processing of milk, small farms use only cream separators or separators, which is the same thing. Cream separation occurs under the influence of centrifugal force, which throws heavy particles to the periphery, while light particles remain closer to the center. After separation, all that remains is to select the fractions into separate containers.

The milk separator is a customized system for the continuous supply of milk into a rotating disc drum and the selection of cream and skimmed milk, or skim milk.

But the process depends on many factors:

- drum rotation speed;

- tasks to obtain a certain ratio of skim milk and cream;

- on temperature and milk flow through the centrifuge.

An experienced user finds his own ratio of all variables and tries to follow it. For the user of a manual device, it is important to catch the required number of drive revolutions manually. The electric milk separator is set up in advance using the mode buttons.

How to make a milk separator with your own hands?

If you do not have the opportunity to make such a purchase, you can try to assemble a milk separator with your own hands. To do this, you will need a chute for supplying milk, a perforated drum, two pipes for supplying skim milk and cream, cups with perforated metal and a centrifuge motor. You can take the motor from the centrifuge by disassembling an old activator washing machine. Keep in mind that a homemade milk separator is not easy to assemble due to the fact that the component parts may not fit each other perfectly. To make the body, you will need a steam-type juicer, but you will have to upgrade it a little. To do this, we advise you to listen to the following tips:

- Extend the tube designed to connect all the compartments of the juicer.

- Make a hole in the "upside down pan" so that the tube can come out.

- Use the juice container as a container to collect the cream.

The electric drive should be located at the bottom of the future separator. Otherwise, you will have to select a motor depending on the height of the lower pan. You may need to change the lower pan to a higher version

How to replace a milk separator. How to choose a milk separator: operating principle, differences, prices

Often, choosing a milk separator begins to turn into a search for a “needle in a haystack.” In this article we will help you decide on the choice of separator, paying attention to their main features and giving examples from our range.

Milk separator - divide and conquer!

How to choose a milk separator

A milk separator will be useful for those who are determined to independently obtain cream and butter at home, in the country, in the village. And there really aren’t that many problems with choosing. The main thing is to decide:

- How much milk are you going to separate?

- how often do you need to separate?

The choice will depend on this question:

- separator performance

- component material (plastic or metal)

And the answer to this question is more appropriate: “”

How the milk separator works:

At first, cream was obtained from milk by simply settling the milk, waiting almost a day for it to float to the top. This is the so-called “gravitational method”.

It took a long time, but in 1878 everything became simpler: the centrifugal separator was invented by the Swedish scientist Carl Gustaf Patrik de Laval. And now, although it has changed its shape and materials, it has become electric, and not just manual, but the principle remains the same:

A separator (lat. separator - separator) is a device that, using centrifugal force, separates the product into fractions of different densities. In milk, this is divided into skim milk and milk fats.

During the industrial processing of milk in large volumes, for additional purification, in addition to filtration, “bactofugation” is used, i.e. Centrifugal force is used to remove microorganisms from milk.

The so-called “centrifugal milk separation”. With simultaneous pasteurization, this allows you to get rid of up to 99.8% of the total number of bacteria. (more about this)

Here's how a typical household separator works:

★ in the separator drum, whole milk is spun at a speed of more than 1000 rpm; the heavier component of the milk is the “tops” (cream), i.e. milk fats are thrown by centrifugal force to the walls of the separator

★ and less heavy milk, devoid of milk fat fractions, remains closer to the center of rotation in the separator bowl and cream and skim milk flow out through separate drains.

How to assemble a milk separator?

There are quite a lot of models of separators from different manufacturers, and it is better to assemble them according to the personal instructions for the model.

General tips “how to work with a milk separator”:

- when collecting funnels (aluminum or polycarbonate plates), the same ones that rotate at different levels, creating a centrifugal force that separates the skim milk and cream), you need the specified order of these funnels. Although they seem similar, they are usually of 2 different types. They need to be arranged alternately.

- there is a nuance regarding, for example, the Motor SICH SCM-100-18 separator (aka Sokol MS 100) - polycarbonate “funnel” plates, unlike aluminum ones, can be folded in any order

- Check the temperature of the milk during separation: the milk should be about +35-40°C and the milk receiver (a large container for milk on top of the separator), and the separator drum, it is better to “heat” before separation by running a couple of liters of warm water at a temperature of +45-50°C.

- The previous point (preparing the optimal separation temperature) is also useful in that, when running the water, you will see and check how correctly you have placed the funnel plates: if water comes out of the cream receiver (the upper groove for draining the cream), then you have assembled the separator drum incorrectly. Water, as well as return water, must drain from the lower receiver

How to choose a milk separator?

If assembling a homemade milk separator seemed too labor-intensive to you, and you don’t want to waste time on it, we recommend buying this equipment. The price of the most budget separator on the domestic agricultural machinery market starts from 1,000 UAH.

The variety of separator models on the shelves of retail outlets or in an online store can make your head spin. The recommendations below will help you not to get lost in your choice.

- Determine the conditions for installing the separator. If you have problems with wiring, you definitely shouldn’t buy an electric separator, so that its operation does not lead to dire consequences both for the premises and for you personally.

- Decide on the desired lifespan of the device. The most durable separators are made of metal, which allows you to extend their service life for several years to come. Although some plastic models may be of quite good quality, we recommend that you carefully look at the reviews and technical characteristics of the equipment.

- Pay attention to the power of the device. Powerful separators can process large volumes of raw materials in a minimum amount of time. When choosing a separator, rely on the tasks you set for this equipment.

- The cost of the separator also plays an important role. Indicate your desired price range and decide on a model based on the above criteria.

Milk separator at home

Experienced farmers know that it is not always possible to sell or sell fresh milk. Often there is a need to degrease it. Or make sour cream, cottage cheese or cheese from sour milk. Typically, these foods may take a day or more to prepare. A milk separator will help you cope with these tasks in just one hour.

If you are breeding cows, sheep or goats, milk separation equipment will be useful to you in any case, regardless of the size of the herd.

Thus, you will increase the efficiency of your enterprise and, accordingly, will receive greater profits.

Even if you don’t have a farm and you just want to pamper your family with fresh and high-quality dairy products, a milk separator will also come in handy.

Design and principle of operation of the separator

The separator consists of a cylindrical drum, a plate separator, a set of conical disks (plates), a shaft, three receivers for milk, cream and skim milk, a housing, a chamber with a float, a reflector, a plug, a bushing and a support.

Equipment for milk separation is divided into manual and electric. Unlike a manual separator, an electric separator is equipped with an electric motor, therefore, accordingly, it works using electricity.

This is their main difference.

A milk separator is a device that allows you to separate the fatty fractions of milk from its liquid part.

The operating principle of a milk separator is as follows: under the influence of centrifugal force, the main part of the milk is beaten to the walls of the equipment, and the cream is beaten to the center. As a result of separation, we obtain pure skim milk (skimmed milk) and cream.

For example, if you want to separate six liters of milk, you will get five liters of pure milk and one liter of cream. That is, the ratio of parts is one to five.

Using the separator you can prepare cream, butter, cottage cheese, yogurt and fermented milk drinks.

How to make a milk separator with your own hands?

If you do not have the opportunity to make such a purchase, you can try to assemble a milk separator with your own hands. To do this, you will need a chute for supplying milk, a perforated drum, two pipes for supplying skim milk and cream, cups with perforated metal and a centrifuge motor.

You can take the motor from the centrifuge by disassembling an old activator washing machine. Keep in mind that a homemade milk separator is not easy to assemble due to the fact that the component parts may not fit each other perfectly. To make the body, you will need a steam-type juicer, but you will have to upgrade it a little.

To do this, we advise you to listen to the following tips:

- Extend the tube designed to connect all the compartments of the juicer.

- Make a hole in the "upside down pan" so that the tube can come out.

- Use the juice container as a container to collect the cream.

The electric drive should be located at the bottom of the future separator. Otherwise, you will have to select a motor depending on the height of the lower pan. You may need to change the lower pan to a higher version

How to choose a milk separator?

If assembling a homemade milk separator seemed too labor-intensive to you, and you don’t want to waste time on it, we recommend buying this equipment. The price of the most budget separator on the domestic agricultural machinery market starts from 1,000 UAH.

The variety of separator models on the shelves of retail outlets or in an online store can make your head spin. The recommendations below will help you not to get lost in your choice.

- Determine the conditions for installing the separator. If you have problems with wiring, you definitely shouldn’t buy an electric separator, so that its operation does not lead to dire consequences both for the premises and for you personally.

- Decide on the desired lifespan of the device. The most durable separators are made of metal, which allows you to extend their service life for several years to come. Although some plastic models may be of quite good quality, we recommend that you carefully look at the reviews and technical characteristics of the equipment.

- Pay attention to the power of the device. Powerful separators can process large volumes of raw materials in a minimum amount of time. When choosing a separator, rely on the tasks you set for this equipment.

- The cost of the separator also plays an important role. Indicate your desired price range and decide on a model based on the above criteria.

Where to buy a milk separator?

You can find the best value for money in the Cropper online store. Convenient and comfortable site navigation allows you not to get lost in the variety of separators and choose the option that would best suit you. In addition to separators, visit cropper.com.

ua also sells incubators, feed cutters, smokehouses, distillers and milking machines. You can pay for the goods upon receipt, by money transfer to the company's account or by bank card. The Cropper store sends parcels using the Intime, Delivery and Nova Poshta postal services throughout Ukraine.

Kharkov residents can also pick up their order from the courier.

Source: https://damilk.com.ua/novosti/separator-dlya-moloka-v-domashnih-usloviyah/

DIY milk separator

Milk contains many useful substances, vitamins and minerals. The benefits of milk are evidenced by the fact that by drinking 0.5 liters of milk a day, the body receives all the nutrients it needs. True, this applies to a greater extent to fresh milk; sterilized milk has significantly fewer beneficial properties.

Milk contains lactose, which is necessary for the functioning of the heart, liver, and kidneys. The main protein in milk, casein, contains the amino acid methionine, which is also beneficial for the liver and kidneys. Do-it-yourself milk separator However, some people do not have the lactase enzyme in their gastrointestinal tract, which breaks down lactose (milk sugar). Such people cannot tolerate milk, but can benefit from fermented milk products. Lactic acid bacteria suppress the activity of intestinal microflora and thereby reduce the adverse effects of lactose.

Milk contains beneficial vitamins. Vitamin A, which is necessary for the growth of a child and is also essential for maintaining vision. Vitamin B1 (thiamine), necessary for the absorption of sugar.

The body receives the calcium it needs from milk and dairy products. After all, calcium tends to be washed out of bones with age and the bones become fragile. Calcium is necessary both for children’s bodies to form the skeleton, and for older people to prevent osteoporosis. And lactose contained in milk helps the body better absorb calcium.

The beneficial properties of milk will be enhanced if you combine milk intake with vitamin D to enhance the absorption of calcium in the intestines. Fish, fish oil, and caviar are rich in vitamin D.

Fresh milk has bactericidal properties only for 3 - 4 hours after milking. DIY milk separator Then microorganisms and bacteria begin to multiply in it. Raw milk must be boiled before consumption, even if you buy it from reputable places.

Boiling kills bacteria and most spores.

Sterilization kills all bacteria and their spores. True, during sterilization (heating to 125 - 145 degrees) vitamin C and useful proteins - albumin and globulin - are destroyed. But such a product can be stored for a long time.

Pasteurization of milk - heating to 74 - 76 degrees is the most optimal way to process the product; during pasteurization, most vitamins are preserved. but the shelf life of pasteurized milk is much shorter: at a temperature of 0 to 6 degrees, the shelf life is no more than 5 days. It is not recommended to boil pasteurized milk.

The beneficial properties of milk include its beneficial effect on the gastric mucosa. Milk is especially useful for gastritis (goat milk is most useful). Do-it-yourself milk separator Milk is also useful for sleep disorders. Drink milk with honey before bed, it is very calming.

In general, milk with honey has a whole range of healing properties, strengthens the immune system, and increases the body’s resistance.

Drink milk in small sips, as milk can curdle in the stomach into hard-to-digest clumps. In case of food poisoning, on the contrary, drink the milk in one gulp, then the toxic products will come out faster.

Baked goods with a high sugar content will turn a more uniform brown color if you add powdered sugar to the dough instead of granulated sugar.

Price for household milk separators

In general, the price on the Russian separator market generally corresponds to their quality. The cheapest manual separators cost from 2,200 rubles. True, already for 2580 rubles. You can also buy an electric ESB-02, which with its productivity of 50 liters per hour is not so bad, but before making such a purchase, we advise you to look at the reviews for this model. By the way, we recommend doing the same for other inexpensive separators. This does not mean that they are not worth purchasing, but you must compare their quality and characteristics with your needs. The most detailed model of the separator Motor Sich SCM-100-18, which we described today, costs 7100 – 7200 rubles, while the plastic modification with the index “19” will cost you 500 – 700 rubles less. The price of its competitor, the Farmer ES-02 separator, is approximately in the middle and amounts to about 6,900 rubles. The ES-01 model costs just over 6 thousand. It remains to add that milk for processing in any separator should be slightly heated - to a temperature of 40 - 45 ° C - for better separation into fractions. Finally, a short overview of separators:

We recommend other articles on the topic

Choosing a chainsaw for your purposes, which brand should you choose?

How to choose the right drill for your home based on future work

Homemade drilling machine, design options, choice of materials, drawings

How to choose a circular saw - a circular saw for wood for home and country use

Household milk separator

People running households in villages often keep cows: one, two, or even more. The fresh milk obtained after milking is used for household needs, for sale to visitors or village residents, but it is not always possible to fully sell it or consume it at home. When a large amount of dairy product is collected, it makes sense to process it. A household separator, which is much faster and more reliable than traditional gravity settling or a butter churn, will help you make long-lasting cream or butter from milk.

Operating principle of household milk separators

Previously, processing milk into butter or cream used manual methods that took a lot of time, effort and required certain temperature conditions. For the first time, separators separating water from cream were invented for industry - this allowed factories to produce large volumes of dairy products. Huge containers, in which cow's milk is processed due to centrifugal force, require large capacities and are not suitable for household use, so small separation devices began to be produced.

A small household milk separator, as a rule, weighs about 3-4 kilograms and is capable of producing more than fifty liters of milk products in an hour - its power should be enough for a small farm. The resulting cream will surpass in quality those sold in supermarkets and stores, because only fresh, recently collected milk will be immersed in the separation container. In addition, the owner monitors the production process much better, compliance with sanitary standards, as well as the health of the cows that provide the product for processing.

Every experienced owner can use a household milk separator to whip butter. To do this, you need to settle the finished cream for some time, and then carry out the separation process. The resulting product must be compressed under pressure and then stored in a cold place. Some devices are initially equipped with the option of churning butter; some are also sold that serve exclusively as a butter churn. Read below about what types of household milk separators there are, what to look for when purchasing and which companies produce them.

What to look for when choosing a household separator

Home milk separators differ in power and in the volume of products processed per unit of time. The quality of the final product is affected by the material from which the device is made, and the type of separation device - mechanical or electrical. You need to choose a separator based on your needs and the size of your home dairy production. Most devices cost less than 5,000 rubles, so every owner will find a suitable option for himself.

Volume of milk to be processed

Before purchasing a household appliance, you need to calculate how much dairy products are planned for processing. Home separators can produce from 50 to 80 liters per hour. Owners of a small farm, where the number of cows does not exceed three, should pay attention to simple devices with a minimum displacement. Their productivity is more than enough to process milk fractions into cream or butter. If a person owns a small farm, give preference to those units whose capacity is higher - up to eighty liters.

Material from which the separator is made

The material used to make a household separation device plays a role in the quality of the product. For example, metal milk separators last longer due to the durability of the mechanisms, while machines made of plastic are more likely to break down and become unusable. However, people who know how to carefully handle equipment and will take care of it are not afraid of a quick breakdown of a plastic device. Metal household separators are mainly of the manual type, and this is not convenient for everyone.

Device type: electrical and mechanical

There are two types of separation machines: mechanical and electrical. Each has its own advantages and disadvantages, which need to be carefully studied before purchasing equipment. For example, a mechanical manual milk separator is based on the use of muscle force. The main advantage of this device is the ability to work without being connected to the mains. Especially in a village where power outages are not uncommon, it will be convenient to have a mechanical milk separator. The risk of breakdown of manual equipment is much less, and the design is easier to repair.

Electric separators are preferred by those who need to process large volumes of dairy products. For example, if there are about three cows or more on the farm, it will be physically impossible to manually make cream after milking. An electric separator for milk is capable of making the same number of revolutions as a mechanical one, but due to voltage fluctuations it can fail. To avoid this unpleasant situation and not find yourself without a useful device, many owners of small farms purchase 2 types of equipment at once.

Functionality

Before you choose a milk separator and buy it, you need to study the functionality of the device. For example, there are bowls with a capacity of just over five liters that can process about eighty liters of milk fractions per hour. You will have to add milk every four minutes, so it is better to take a device with a large bowl volume. A reliable motor for a home milk separator is also important, which can easily withstand voltage surges, and even better, be equipped with special protection.

Which household milk separator is better to choose?

Many companies produce separators for the production of cream and butter, but how to choose the right one? When purchasing, you need to pay attention to the material, type, functionality of the device; you should buy equipment only from trusted companies that have proven their worth. A household milk separator must meet sanitary standards, be equipped with a reliable design, and be convenient for use at home even in small spaces. Read more about separators that are presented on the Russian market.

Milk separator Motor-Sich

Motor Sich is a representative of electric separators for the home, which consume 60 watts. The cost of the devices varies from 3,700 to 5,400 rubles; they are presented in plastic and metal casings. In cheap models, the float chamber is plastic, while the separator for 5,400 rubles is equipped with an aluminum mechanism. The capacity of the bowls is 12 liters. Milk capacity varies from eighty to one hundred liters, so the separator is perfect for a large household. The approximate weight of the devices is 4-6 kilograms.

Household separator Rotor (Altai)

The separator (Altai) is represented by a model for 2,250 rubles - it is an electrical device that can process about 55 liters per hour. The power consumption of the machine is 100 watts. The capacity of the milk receiver is 5.5 liters, weight is 3.5 kilograms. Manufacturers tell you how to use a milk separator in the product description. To begin, pour water into the milk receiver while the electric device accelerates. The acceleration process takes a little over a minute.

Separator Salute

The separator is represented by an electric model for 4,000 rubles, which has a protection system against voltage surges - even with a significant decrease in current, a high-quality machine will be able to continue working. This device has a butter churner function, and adjusting the speed will allow household owners to get skim milk rather than cream. Approximate milk processing per hour is 50 liters, bowl volume is 5.5 liters. The home separator weighs only 3.4 kilograms.

Cream separator Ural-M

The Ural M household cream separator for 3,100 rubles is an electrical device that consumes no more than 100 watts of electricity during operation. The assembly is equipped with a powerful motor that does not make too much noise, is reliable, can work for up to a day without overheating, and does not require changing brushes. The motor has good protection against overloads and voltage surges, which can cause damage to the device. In an hour, farm owners can pass up to 80 liters of milk through a home separator. Bowl volume – 5.5 liters. Weight – 3.5 kilograms.

How to make a chip extractor with your own hands

As mentioned above, first we need to prepare a metal tank, which in the design of our device will serve as a sump. It is allowed to use almost any container (bucket, pan, etc.), but we will take a large metal fuel tank with a volume of 200 liters, which can be found at almost any motor depot.

And the first thing we need to do is check to remove the top cover. And in order to make our chip separator completely sealed with our own hands and not allow sawdust to spill out during the cleaning process, we will make a sealed fastening of the separator to the barrel. Directly for the manufacture of the separator itself, we will use a furniture panel made from 30 mm boards, since I did not have plywood with the diameter of a barrel.

The choice of the height of the future separator depends solely on the size of the socket of the vacuum cleaner hose. For example, with a socket diameter of 58 centimeters, the optimal height of the separator will be 65 centimeters. Such size restrictions are due to the fact that the lower the separator is, the higher the filtering capacity of the equipment will ultimately be.

Next, we outline the dimensions of the separator on the shield. This can be done using a regular compass. The main condition is that the base of the separator must overlap the upper opening of the tank by at least a few millimeters.

We sand the edges with sandpaper, and sand the top and bottom surfaces with a sanding machine. We make the second circle in exactly the same way, but from plywood, which will be a centimeter to one and a half smaller than the first circle. We will use a larger diameter one made from boards as the bottom cover of the separator, and a circle of smaller diameter as the top cover.

Then it is necessary to prepare the annular walls for the separator. To do this, we need thin, highly flexible birch or poplar plywood. Here it is necessary to keep in mind that plywood can bend differently in different directions. For example, along the longitudinal fibers it can bend well in any direction, whereas when bent along the transverse fibers it breaks even with slight bending attempts.

Therefore, it is necessary to decide in advance in which direction the plywood is bent, and if the length or width of the sheet is not enough to make a solid strip, then you can make two plywood blanks, which are then glued together.

I didn’t have plywood of a suitable thickness, so I had to make a ring wall from a sheet of ALUMINUM COMPOSITE PANEL or simply (alucobond), 4mm thick

In the upper disk we will make a groove 4 millimeters deep, in the lower one - 6 millimeters. With a separator height of 70 centimeters, the width of the strip for the wall of the device will be 80 centimeters. The strips can be cut with anything - a circular saw, a milling machine, a jigsaw, etc. The main thing is that in the end the walls should be perfectly smooth, since any protrusions will create swirls, thereby reducing the quality of separation.

At the next stage, grooves are milled in the covers to install the walls. It is necessary to mill grooves on both parts with the same router settings, because even with the slightest additions of tenths of a millimeter, there is a risk that the side wall will become tapered and seriously complicate the assembly of our device. We mark on the lower and upper circles the place where the cutter will go and set the required depth of the groove on the milling machine. After preparing all the parts, we assemble the walls, top and bottom cover.

At the next stage of work, we prepare a triangular-shaped workpiece from a small wooden block and drill a hole in it intended for the hose pipe from the vacuum cleaner. We insert the inlet wedge for the hose into the side wall of the separator. In the same way, we prepare holes for the vacuum cleaner hose in the center of the top cover.

At the base of the separator, which will cover the metal tank, we need to prepare an annular slot - through it the chips will fall into the sump. Finally, we glue a gasket onto the bottom cover for a tight seal and attach our chip separator to the metal tank. We connect the horizontal separator to a regular vacuum cleaner and check how our device works.